Case Study

Case study: Bonding Automotive Interiors

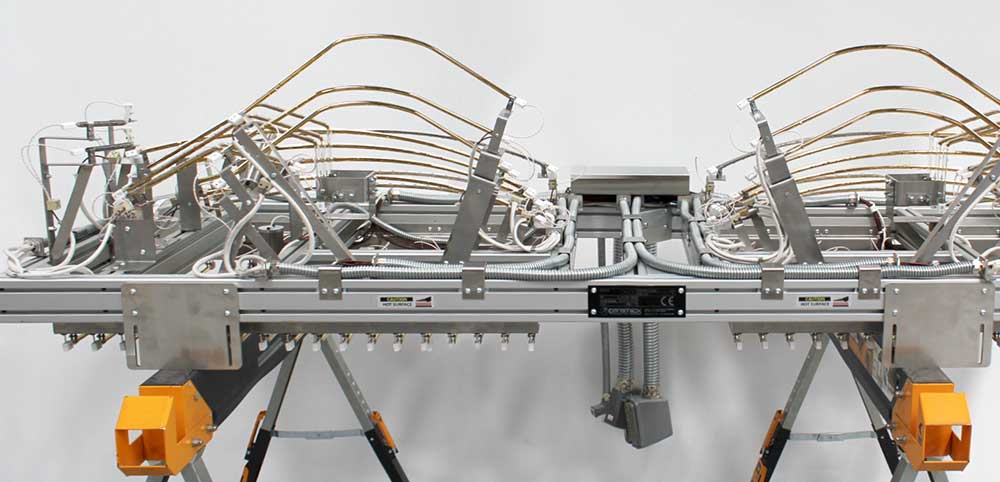

One of the biggest US automotive companies were looking for a more automated solution to their production process. Their Tier 1 supplier made contact with our business partner in the United States, Weco International. They wanted specifically an infrared heating system to bond leatherette materials to the interiors of automotive passenger doors for the cars that they were producing. They had multiple parts, so they needed multiple heating systems.

Ceramicx designed and built the infrared heating system to suit this automotive thermoforming application. Ceramicx designed a one-of-a-kind heating system that consisted of 37 custom heaters that suited the shapes that the customer wanted. This ensured uniformity of heating over the entirety of the part. Ceramicx designed these custom fast medium-wave, Quartz Tungsten Tubes, to suit the material that the customer was processing to ensure it was the most efficient way of heating the material. An additional benefit incorporated in to these heaters was the incredible speed at which they reached temperature to minimise further loss of time for the customer. Ceramicx built 8 different systems in total and ensured all the systems could fit in the one machine.

| Oven Frame: | Aluminium Profile |

| Reflectors: | None |

| Upper Element Type: | Individual Custom Quartz Tungsten Tubes |

| Lower Element Type: | Quartz Tungsten Tubes |

| Controller: | Siemens S7 1500 PLC |

| Control type: | 48 Zones |

| Control feedback: | IR Sensor |

| Total Power: | 148.5kW |

| Oven Size: | 8 heating systems with footprint 2.2m x 0.80m |

The construction of the systems was made in aluminium profile, and custom stainless-steel brackets were made on site in Ceramicx to hold each heater in place. One frame of the heating system consisted of a lower bank of heater that simply consisted of straight quartz tungsten heater that were primarily used to heat the leatherette fabric. The upper heaters were all different to exactly match the surface shape of the part being heated. Finally, one control panel was supplied for all 8 heating systems. A standard connecting point was run off each machine so each system could be changed over easily.

Currently this fast medium-wave infrared heating system is being used in production, and the report is that the end user is satisfied with the result. Our custom built system fit into the footprint that they had available, each system can be changed out easily, the heaters heat the required part uniformly, they are efficient both in response and heating the targeted material, and lastly it is clean energy.