- About

- Heating Solutions

-

-

- Heating Solutions

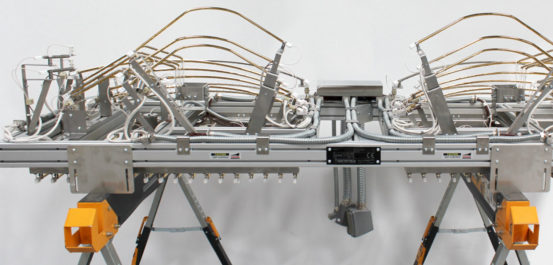

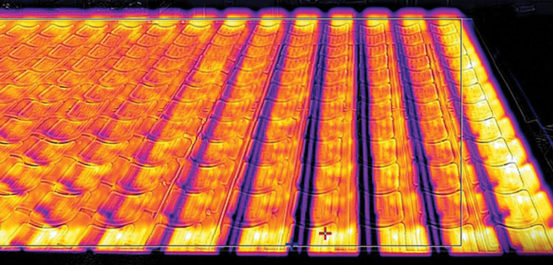

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghi in East China ... Read moreChinaplas 2025

-

-

- Industries

- Enquiries

- Contact us

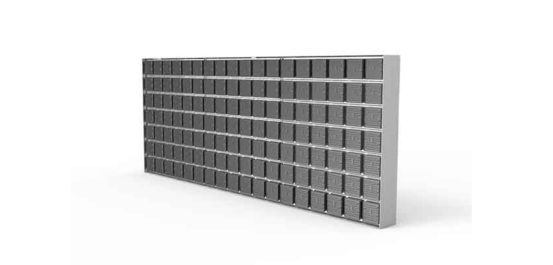

- Ceramicx Components

Your choice of solution and its abilities will always be material and process dependant, but whether it’s short, medium, or longwave infrared heat, we’ll design a system that meets your requirements.

Ceramicx’s industrial ovens draw on the company’s vast experience in applications engineering and ‘heatwork’ development.

Our heating systems are custom designed to each and every customers’ needs be they short, medium or long-wave. This choice is always material and process dependent, however the installed power is always specified according to our rule: ‘As much as necessary, as little as possible’. Ceramicx will advise you in regard to best infrared practice.

Drag to see more industries

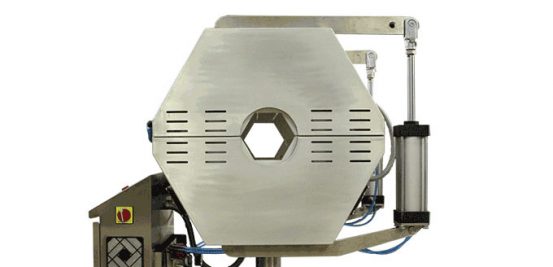

Ceramicx’ Portable Test Stand allows for quick and consistent testing of materials.

Various long, medium, and short wave Infrared emitters are fitted in a modified projector. The emitters face down and heat a material that is placed on a stainless steel mesh.

We look forward to hearing from you

Get in touch with one of our infrared heating experts

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghi in East China ... Read moreChinaplas 2025

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghi in East China ... Read moreChinaplas 2025

Ceramicx management team

Following the retirement of Frank Wilson, Ceramicx would like to announce the appointment of Paddy Martin as Managing Director. Paddy ... Read moreCeramicx management team

St Patricks Day 2023

Happy St Patricks Day 2023 to all our Customers, Suppliers, Employees and Friends. St. Patrick’s Day, Friday 17th March is ... Read moreSt Patricks Day 2023

Warmest Christmas Wishes 2022

Wishing all our customers, suppliers, employees and friends a wonderful Christmas. Please note will close for our Christmas Holidays at ... Read moreWarmest Christmas Wishes 2022

Gain The Competitive Edge With Ceramicx Contract Manufacturing

Ceramicx contract manufacturing Contract manufacturing (CM) works on the traditional basis of outsourcing and setting up a manufacturing agreement between ... Read moreGain The Competitive Edge With Ceramicx Contract Manufacturing

“The new IR system provided by Ceramicx was delivered in a timely manner within budget.

The pre-heating process improvements to our embossing equipment have increased production and reduced scrap within the extrusion process.”