Infrared thermoforming solutions for food & drink packaging

Infrared heating technology is at the heart of the food packaging industry. It’s a sector where Ceramicx are designing and building custom infrared thermoform heating systems for packaging clients around the world. Helping them to manufacture their products quickly, our IR heat technology also means production is completed with precision control, minimal waste and energy efficiently.

Ceramicx supplies award-winning IR heat technology to the world’s leading packaging companies and the reason is simple: IR heat sources reduce both running cost and carbon footprint. A retrofit system from Ceramicx typically reduces energy consumption on a production line by some 40% and can increase production by as much as 20%.

The world of packaging is fast changing as companies become more responsive to consumers and more conscious of energy costs and environmental needs.

Learn about some infrared heating solutions for the Food & Drink Packaging industry that we have developed –

-

Annealing and Stress Relief Oven

Learn moreThe conveyor length was specified by the customer but Ceramicx chose the belt material and specification that was heat resistant. Perforated aluminium was used for the back cover to allow ventilation in the wiring area.

-

Ceramicx Modular Infrared Conveyor Oven

Learn moreEach IR oven module is attached to the next module by means of securing fittings. Side conveyors run alongside the oven modules to feed product to the entry point of conveyor oven. Each oven module has an integrated control system to control heating, air flow, and conveying operations.

-

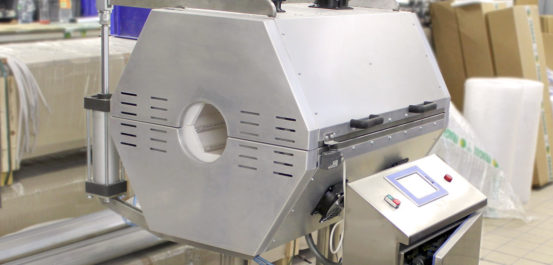

Clamshell Oven

Learn moreThe clamshell shape was ideal for curing the outside layer of a synthetic material used in the drinks industry.

-

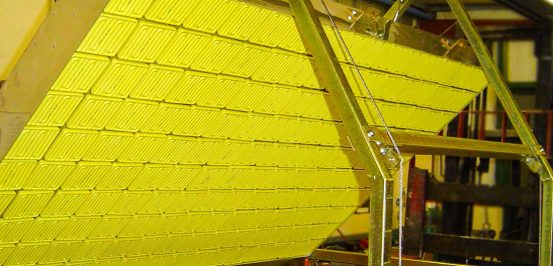

Enhanced Plastic Welding System Using Quartz Elements

Learn moreUsing infrared heat for the first time, the medium-wave elements provide the fast, consistent, and efficient results needed for welding high-density polyethylene (HDPE) pallets.

-

In-Line Thermoforming Oven Solution

Learn moreThe UK based company called Linpac Packaging provides rigid and flexible packaging solutions to customers around the world. They approached Ceramicx to design and build a new heating system that could integrate into their current machine.

-

Lightweight Drying System For Food Manufacturers

Learn moreOpting for Ceramicx 1000W, square flat solid elements (SFSE), these perfectly suited the application. The system had several custom design requests, including a non-standard, smaller frame, lighter grade steel to reduce the system’s overall weight, and an open back for airflow when in use.

-

MSE look to infrared to overcome system inefficiencies

Learn moreA key part of our recommendation was that their state-of-the-art machinery should be fitted with arrays of industry standard ceramic, square hollow elements (SFEH). With a flat body, these particular elements have a much shorter heat up time, increased energy efficiency, and have the ability to produce a diffused, radiant output-to-target distance.

-

Upgrading Food Packaging Thermoforming Lines

Learn moreThe client required a complete upgrade on one of its main plastics thermoforming lines – manufacturing consumables for the food service industries. The project scope included removal of the existing oven and replacement of it with an efficient ceramic-based top and bottom panel heater infrared oven.