- About

- Heating Solutions

-

-

- Heating Solutions

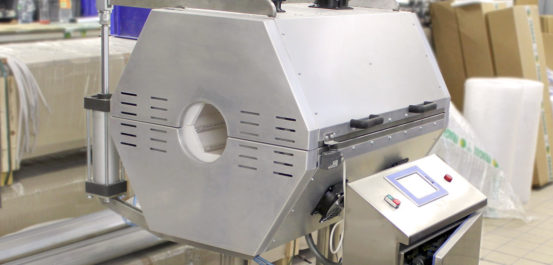

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

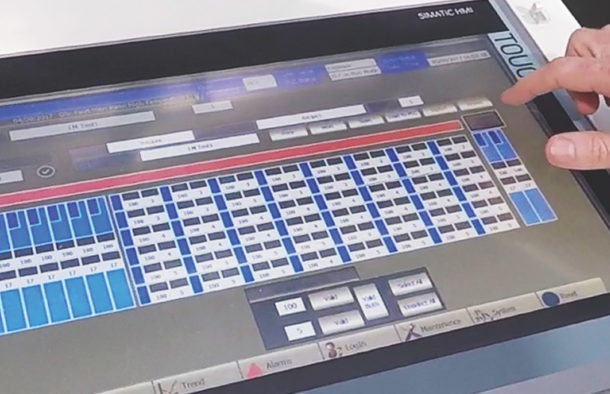

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghi in East China ... Read moreChinaplas 2025

-

-

- Industries

- Enquiries

- Contact us

- Ceramicx Components

Industrial Infrared Heating Solutions

Home Heating Solutions

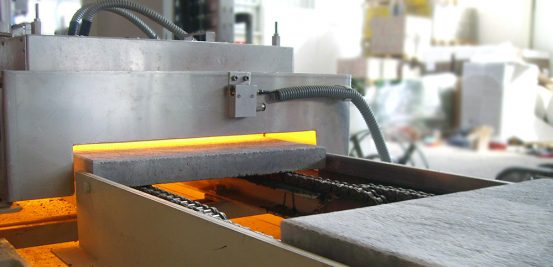

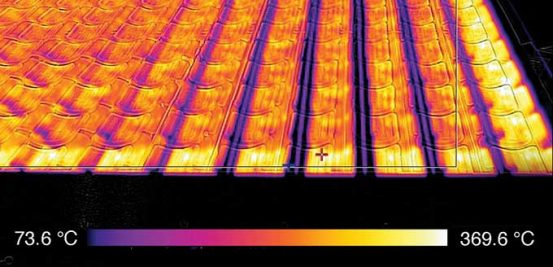

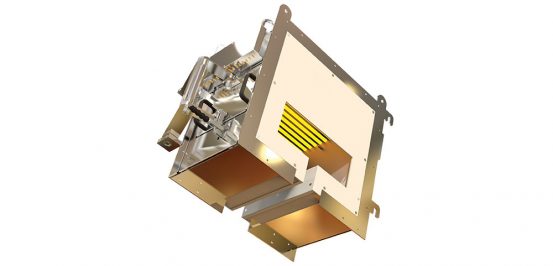

For specialist applications and materials testing, Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

Drawing on a wealth of in-house knowledge and experience in application engineering and heatwork development, each oven is built to precise customer requirements. Each oven or system can be produced to sit within any existing frameworks or as complete, standalone systems capable of integrating into other machinery.

The choice of short, medium, or long wavelengths for any custom oven or heating system will be dependant on your chosen application process. The installed power is always specified to our rule of ‘as much as necessary, as little as possible’.

We also keep the entire infrared process under one roof. That way, we’re able to give you an end to end service that takes care of your own unique oven, from modular, precision solutions to custom-built, high temperature ovens for specialist testing.

These case studies are examples of what we have done in the past to give you a better idea of what we can do for you. See our Infrared Solutions Case Studies Guide also.

Control systems

By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

Read more

FILTER SOLUTIONS

-

42kW Curing Oven

Learn moreCeramicx designed and built a 42 kW long-wave tunnel oven for a USA based electronics customer which was supplied in two sections. The infrared oven system was curved to ensure optimal and uniform heating of the customers material.

-

Aerospace Industrial R&D Furnace Oven

Learn moreWeco International, our business partner in the United States introduced us to the client, a private aerospace manufacturer that provides spaceflight services. The client needed a heating system that could replicate the conditions of atmospheric re-entry in a controlled setting.

-

Annealing and Stress Relief Oven

Learn moreThe conveyor length was specified by the customer but Ceramicx chose the belt material and specification that was heat resistant. Perforated aluminium was used for the back cover to allow ventilation in the wiring area.

-

Bonding Automotive Interiors

Learn moreOne of the biggest US automotive companies were looking for a more automated solution to their production process. Their Tier 1 supplier made contact with our business partner in the United States, Weco International.

-

Case Study: Carbon Fiber Heating System For Aerospace

Learn moreAs an independent, national centre for the world-class design and manufacture of composites, our client’s testing production capabilities were already meeting multi-sector demands.

-

Ceramic Infrared Heating System for PVC Pipes

Learn moreCeramicx combined all the customer’s variances and produced one heating system that could work on all the variations of PVC pipe.

-

Ceramic Infrared Panels for a Consistent Drying Process

Learn moreTo keep their current processes up to date, the customer needed specialist panels to ensure a consistent heat coverage that would match previous iterations of their older and outdated heaters.

-

Ceramicx Modular Infrared Conveyor Oven

Learn moreEach IR oven module is attached to the next module by means of securing fittings. Side conveyors run alongside the oven modules to feed product to the entry point of conveyor oven. Each oven module has an integrated control system to control heating, air flow, and conveying operations.

-

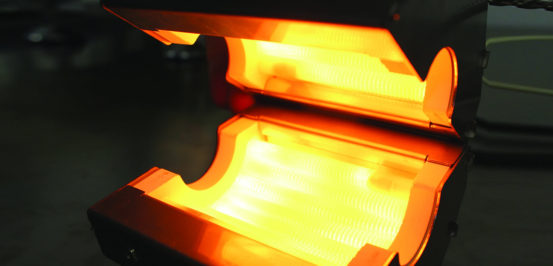

Clamshell Oven

Learn moreThe clamshell shape was ideal for curing the outside layer of a synthetic material used in the drinks industry.

-

Clamshell Pipe Infrared Heating System

Learn moreCeramicx designed and built this clamshell shape heating system for a customer of one of our Danish distributers. The purpose of the shape was to heat the outside of Polypropylene pipes up to diameter of 400mm.

-

Composite Pre-Heat Oven

Learn moreA UK based company specialising in the coating and laminating of complex textiles, and cutting of carbon composite materials, had issues with processing their materials which due to their nature needed very accurate control.

-

Contract Manufacturing: Heatshrink Application

Learn moreWith two infrared heat solutions needed, both had strict specifications in terms of power, temperature, dimensions, and reliability, and both were developed using our infrared quartz heating elements. The clamshell shape was a natural consideration and Ceramicx worked on this using quartz infrared elements components.

-

Creating Weather-Resistant Products For The Construction Industry

Learn moreCeramicx fast response, infrared modular heating technology to create innovative and weatherproof products for the construction and building industries. While giving them an increase in production speeds, the introduction of infrared has also shortened delivery times and improved the aesthetics and finish of their products.

-

Custom Infrared Oven For Injection Mould Tooling Manufacturer

Learn moreThe principal feature of this oven is the inclusion of 16 custom-made, 10kW, shortwave, twin-tube quartz halogen infrared elements controlled via open-loop technology, giving each heater its own individual zone. The oven also includes a pneumatically operated door mechanism with vertical operation.

-

Cut-Sheet Thermoforming Oven

Learn moreA UK based Tier 1 automotive supplier were having some productivity issues. Specifically, they were looking for uniformity of heat to ensure repeatability and consistency of product. They wanted to upgrade their current infrared heating system which consisted of large upper and lower panels.

-

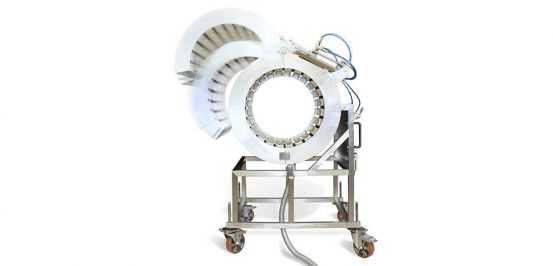

Drying System for Concrete Pipes

Learn moreFriedr-Freek and Ceramicx collaborated on the design. The decision was to provide the customer with an overall octagonal shape in stainless steel frame, with the ceramic infrared heaters facing out to the heat internal section of the pipe.

-

Enhanced Plastic Welding System Using Quartz Elements

Learn moreUsing infrared heat for the first time, the medium-wave elements provide the fast, consistent, and efficient results needed for welding high-density polyethylene (HDPE) pallets.

-

Four Column Vertical Curing System

Learn moreTo heat four separate, composite parts, vertical heater columns were fitted with 22 infrared emitters and 3 pyrometers for precise, non-contact temperature measurement at 1” increments along the material.

-

Glass Forming Oven

Learn moreCeramicx designed and built a single oven heating module for a prominent customer in the United States glass industry.

-

Halogen Infrared Heating Sectors

Learn moreShort lead times for customers is one of the many perks of this process we pride ourselves on. These units were designed for a Norwegian customer for the offshore construction industry.

-

Heat-Shrinking Test Unit For Automotive Sector

Learn moreTo improve an inefficient and slow manual system, Ceramicx were given the green light to design and build a standalone, multi-zone, infrared heating test unit. Using a series of SFEH 600W ceramic infrared heating elements, the system is custom-designed to give a faster process, with more efficiency and consistency in the heat-shrinking of plastic and textile cloth wrapping for rigid rubber tubing.

-

In-Line Thermoforming Oven Solution

Learn moreThe UK based company called Linpac Packaging provides rigid and flexible packaging solutions to customers around the world. They approached Ceramicx to design and build a new heating system that could integrate into their current machine.

-

Infrared Heating Panel Replacement Oven

Learn moreWe proposed two designs to the company. One with ceramic elements and one with quartz elements. The customer decided to go with the option of using our full quartz element heaters, to best match the previous panels in power and size.

-

Inline Material Processing Oven

Learn moreThe infrared oven was designed with 4 zones evenly spread throughout which allowed the heat to be evenly spread throughout the material giving an end result of a high quality material finish. Each zone was capable of being controlled to within 2°C of the specified setpoint which allowed for a fast heat up time and extremely accurate setpoint control.

We look forward to hearing from you

Get in touch with one of our infrared heating experts