- About

- Heating Solutions

-

-

- Heating Solutions

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

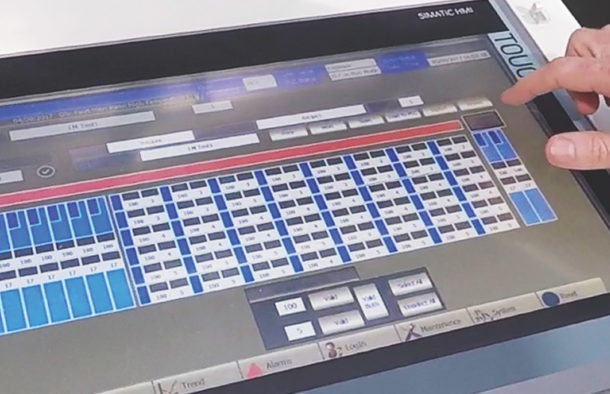

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghi in East China ... Read moreChinaplas 2025

-

-

- Industries

- Enquiries

- Contact us

- Ceramicx Components

Industrial Infrared Heating Solutions

Home Heating Solutions

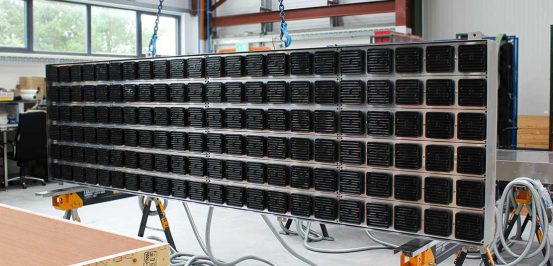

For specialist applications and materials testing, Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

Drawing on a wealth of in-house knowledge and experience in application engineering and heatwork development, each oven is built to precise customer requirements. Each oven or system can be produced to sit within any existing frameworks or as complete, standalone systems capable of integrating into other machinery.

The choice of short, medium, or long wavelengths for any custom oven or heating system will be dependant on your chosen application process. The installed power is always specified to our rule of ‘as much as necessary, as little as possible’.

We also keep the entire infrared process under one roof. That way, we’re able to give you an end to end service that takes care of your own unique oven, from modular, precision solutions to custom-built, high temperature ovens for specialist testing.

These case studies are examples of what we have done in the past to give you a better idea of what we can do for you. See our Infrared Solutions Case Studies Guide also.

Control systems

By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

Read more

FILTER SOLUTIONS

-

Internal Curing of Aircraft Stringers

Learn moreCeramicx have developed a novel heating system for the curing of thermoset resins in the manufacture of composite aircraft stringers.

-

Lightweight Drying System For Food Manufacturers

Learn moreOpting for Ceramicx 1000W, square flat solid elements (SFSE), these perfectly suited the application. The system had several custom design requests, including a non-standard, smaller frame, lighter grade steel to reduce the system’s overall weight, and an open back for airflow when in use.

-

Long Wave Composite Curing Oven

Learn moreCeramicx developed a composite curing oven, which was embedded in a robotic press cell for a variety of composite systems.

-

Material Test Oven

Learn moreCeramicx designed and built and infrared test oven system for a Chinese customer.

-

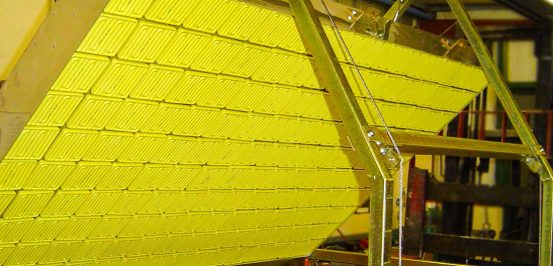

Modular Long-Wave Infrared Heaters In Composite Curing

Learn moreCeramicx SFEH black ceramic heating elements provided the higher temperatures required to fuse the materials, leading to faster curing times. Our inhouse Ceramicx team were then able to draw up drawings for a unique heating system, based on our own Modular IR 260 infrared technology.

-

MSE look to infrared to overcome system inefficiencies

Learn moreA key part of our recommendation was that their state-of-the-art machinery should be fitted with arrays of industry standard ceramic, square hollow elements (SFEH). With a flat body, these particular elements have a much shorter heat up time, increased energy efficiency, and have the ability to produce a diffused, radiant output-to-target distance.

-

Multi-Zone, Infrared Thermoforming Oven For Manufacturing

Learn moreAlready using an older system, with gas catalytic infrared emitters, the biggest concern for the customer had been issues with the zoning of their emitters and the uneven and inconsistent temperatures. The challenge was to create a custom-designed, replacement infrared thermoforming oven that gave more comprehensive sheet heating through multi-zoning.

-

Paint Curing Enclosure Design & Build

Learn moreBased near Macroom, Co Cork, Ireland, Firebird had a recent requirement to streamline and increase the throughput of its boiler production line. This was primarily needed in order to satisfy continuing demand and to circumvent seasonal bottlenecks for Firebird heating products.

-

Portable Test Oven

Learn moreCeramicx’ new Portable Test Stand allows for quick and consistent testing of materials. Various long, medium, and short wave Infrared emitters are fitted in a modified PAS, which is easily attached to the test stand.

-

Pre-Heat and Main-Heat System

Learn moreThese were used to produce an artificial turf type material for sports grounds in the US. There were 2 heating systems: pre-heat and main heat system to be positioned over a conveyor system.

-

Quartz And Ceramic Infrared Heating Systems For OEM Industry Leader

Learn moreUsing a mix of quartz and ceramic trough infrared elements, the new stand alone IR systems would bring efficiency and speed to their processes.

-

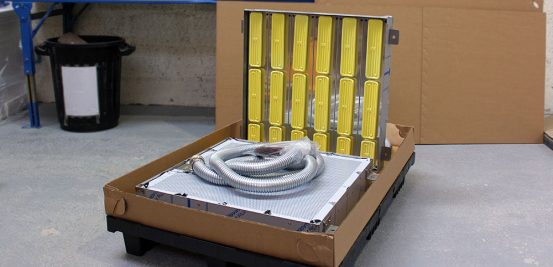

Quartz Infrared Heating Modules

Learn moreCeramicx designed and manufactured the modules in house using Ceramicx PHQE elements (Pillared Half Quartz Element).

-

Santa Fe custom skylights

Learn moreCeramicx were tasked to upgrade an ageing and energy-costing plastics thermoforming line to an infrared-based solution – while remaining well within the power constraints for the local electricity grid.

-

Shortwave Infrared For Pre-Heat & Curing

Learn moreIn the past year, QS Group has increasingly turned to Ceramicx to manufacture shortwave custom-built pre-heat and various curing heating systems.

-

Test Equipment for Aerospace

Learn moreThe aerospace customer wanted some test equipment built to a small scale on a small budget just to see if they could get a result.

-

Thermoforming System Upgrade for Insulation Provider

Learn moreSupplying the construction industry with a comprehensive range of insulation materials, the need for quality and efficiency led Xtratherm to choose Ceramicx for a more reliable and effective custom-built system.

-

Upgrading Food Packaging Thermoforming Lines

Learn moreThe client required a complete upgrade on one of its main plastics thermoforming lines – manufacturing consumables for the food service industries. The project scope included removal of the existing oven and replacement of it with an efficient ceramic-based top and bottom panel heater infrared oven.

-

Vacuum Forming Oven

Learn moreA major Canadian company that makes hot tubs, contacted our distributor in the United States to help them build one section of their machine. They were in process of building a machine to mould hot tubs and they wanted us to do the heat work for the section of their vacuum forming machine.

We look forward to hearing from you

Get in touch with one of our infrared heating experts