The ability to control heat energy output allows the heating process to be fully optimised. With all radiant heat transfer applications there’s a limit to the amount of energy which can be directed at the target over a specific period of time.

Modern manufacturing requires short process times with minimal energy usage. Applying excess heat introduces the risk of surface scorch, making it critical that the heater output can be tuned to provide both process speed and high quality results.

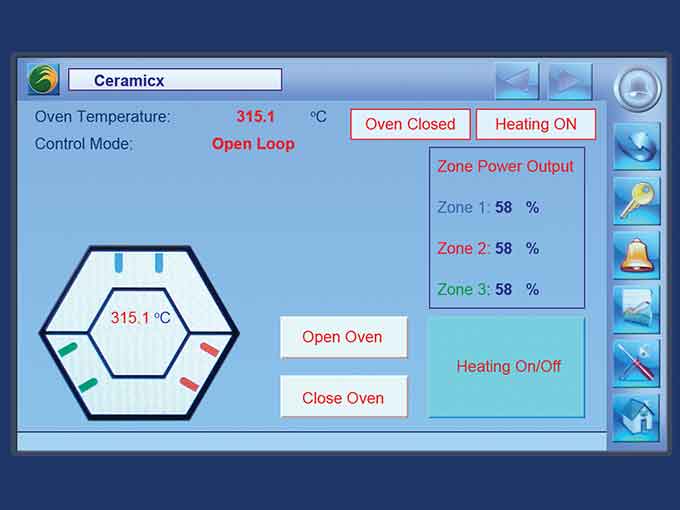

By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that vary in size, from simple, single zone open loop systems to larger, complex multi-zone installations with temperature feedback and closed loop control.

Control Options

Heating control system solutions can be categorised into three key areas:

- Individual zone controllers

- Centralised PLC-based control

- Open/closed loop

Individual Zone Controllers

Individual zone controllers are suited to smaller, less complex systems with a typical zone count of 15 or less. Using individual PID temperature controllers for each temperature control zone required, each controller is individually configured, providing a control signal to a solid state relay or similar power switching device.

Solid state relays (SSRs) are solid state switching devices which normally use back to back thyristors/SCRs or triacs for switching AC loads. Ceramicx normally use zero cross SSRs so the device will only switch on and off at the zero point in the sine wave of the ac supply, minimising the initial surge current which helps prevent electromagnetic interference (EMI).

Another advantage of SSRs over conventional mechanical relays is that they can perform millions of switching operations with excellent reliability when specified and utilised correctly.

Centralised PLC-Based Control

One of the disadvantages with individual zone controllers is that each controller has to be configured individually. Although each controller is configured before leaving the factory, parameters such as setpoint (the desired temperature value) or % power (required zone output on a % time basis) will need to be set by the customer.

For a low zone count this shouldn’t be an issue, but for larger systems (potentially containing hundreds of zones) it’s not a practical solution, especially where process conditions and/or requirements are frequently subject to change. In this case, programmable logic controllers (PLCs) provide the best solution.

As a standard control platform for larger multi-zone projects, we use Siemens S7 series controllers (AB on request). A single, human machine interface (HMI) allows the operator to interact with the PLC which can then be programmed to read all process values (temperatures), set process values, configure alarm thresholds, and operator access levels.

The PLC can be used to directly switch SSRs similar to individual zone controllers, and also facilitates the integration of multi-channel power switching hardware. These systems use the same switching technology as SSRs except they’re installed in cards with multiple outputs which can then be mounted in racks.

The total package can be networked to the PLC and offers a considerable space saving inside the electrical enclosure, as well as a reduction in wiring time, and increased functionality and load diagnostics. Systems incorporating PLCs can also be programmed to exchange digital IO with existing equipment or networks directly to plant SCADA software.

Open/Closed Loop

Both individual zone controllers and PLC-based systems can be programmed to operate in both open and closed loop mode.

Open loop control is the simplest and involves basic power control of the heating load without temperature feedback. Ceramicx normally uses time proportional control where the heating load is burst fired, i.e. turned fully on for a period, followed by an off period. For example, a setting of 50% with a 2 second cycle time results in 1 second on and 1 second off.

Closed loop control involves the temperature control of either the heating system or the target object itself. Where temperature control of the heating system is used, a type K thermocouple is normally incorporated into the heating element. This provides temperature feedback to the controller which will then use proportional-integrative-derivative (PID) control in order to operate the heater at the set value.

Closed loop control of the process is also possible. Normally implemented through the use of non-contact infrared thermometers (pyrometers), these can be used to directly measure product temperature.

Ceramicx solutions

We have the in-house experience and capability to design and build any control enclosure, which includes the required hardware for the control solution that suits your process needs. With most low voltage supply networks catered for, both heating and control systems are fully tested before leaving the factory, helping to ensure seamless integration when installed in the factory.

Where closed loop control from the heater system is used, we ensure the PID functionality is tuned to provide close tolerance temperature control. The supply of ‘quick connect’ plugs and sockets on the heating and control system allows for a short installation time with minimal requirement for skilled electrical personnel wherever possible.