Case Study

Case study: Material Test Oven

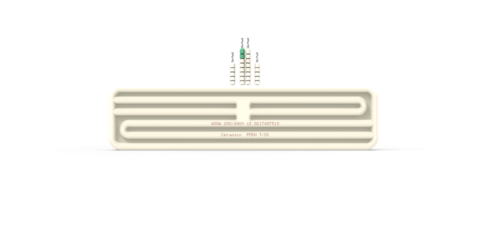

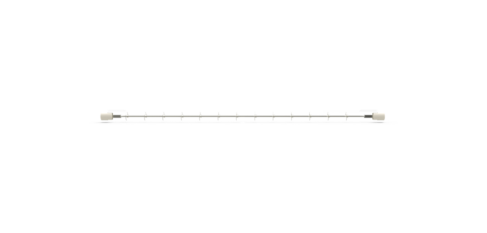

Ceramicx designed and built and infrared test oven system for a Chinese customer. This oven has a series of removable drawers which contain the different heating elements. Long wave ceramic elements, medium wave quartz elements and short wave halogen allowing heater vs material type evaluation.

Control is achieved via closed loop SSRs in conjunction with a non-contact sensor. The unit was designed to be small, highly mobile yet contain a large amount of technology to allow the customer to evaluate, on-site, the effectiveness of Ceramicx infrared heating technologies.

| Oven Type: | Test Oven + Control |

| Total Power: | 6.2kW |

| Power Supply: | 1 x 230V + N + PE |

| Maximum Current/Phase: | 26A |

| Element Types: | Ceramic, Quartz & Quartz Halogen |

| Total Heating Power: | 6.0kW |

| Control channels: | 1 |

| Control type: | 1 zone open loop control |

| Controller: | Siemens S7 1211C |

| Control interface: | Siemens KP300 |

| Power control: | SSR |

| Sheet temperature monitoring: | IR Sensor |

| Footprint: | 0.92 x 0.6m |

| Oven length (entry to exit): | 0.92m |

| Approvals: | CE |