Case Study

Case study: Cut-Sheet Thermoforming Oven

A UK based Tier 1 automotive supplier were having some productivity issues. Specifically, they were looking for uniformity of heat to ensure repeatability and consistency of product. They wanted to upgrade their current infrared heating system which consisted of large upper and lower panels.

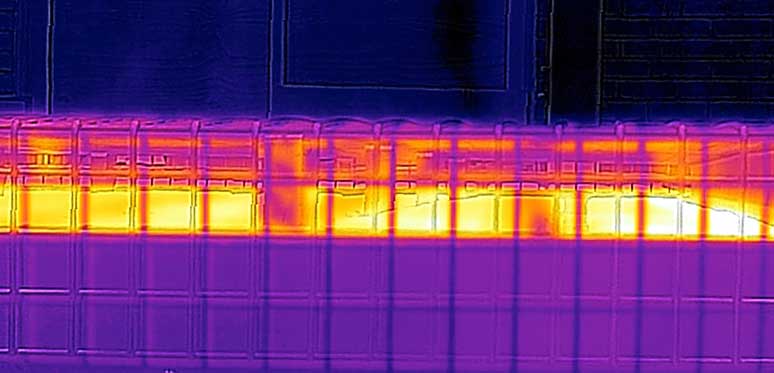

Ceramicx developed and customised the infrared heating system to the material, temperature, power, and time requirements of the process. Top and bottom infrared heating was achieved using HTE long wave ceramic heaters. A total of 18 zones of control were outlined by the customer, and were used around the perimeter of each heating system to minimise edge loss. An upgraded control system was also supplied with the heating system.

The key features of the oven heating system included:

| Oven Frame: | Stainless Steel Box Section |

| Reflectors: | Special aluminium clad steel |

| Element Type: | Long Wave Ceramic model HTE |

| Maximum Operating Temp: | 250°C (Element Temperature) |

| Controller: | Siemens S7 1500 |

| Control type: | 36 zone closed loop control with T/C k feedback |

| Control feedback: | Type K thermocouples integrated into ceramic element |

| Sheet temperature monitoring: | Pyrometer |

| Total Heating Power: | 124kW |

| Oven Size: | 2.08m x 1.80m |

The process was a cut sheet process for the thermoforming of car interior liners – in this case the boot space. Black carpet onto black plastic sheet was robotically loaded onto a moving table and then moved across into the heated zone. Heating the top and bottom of the part for a specified time, the sheet then gets moved on to the surface where it is slowly pressed into the required shape. The component then cools down inside the mould, before it is removed and the trimming and finishing process takes place.

The result was that the customer was extremely impressed with how fast the ceramic heaters got to their required temperature, and the ease at which the IR heaters found and remained at the required temperature set-point. Ceramicx has since worked on another project with this supplier and supplied them with a second infrared heating system for a different manufacturing facility in the UK.