Case Study

Case study: Paint Curing Enclosure Design & Build

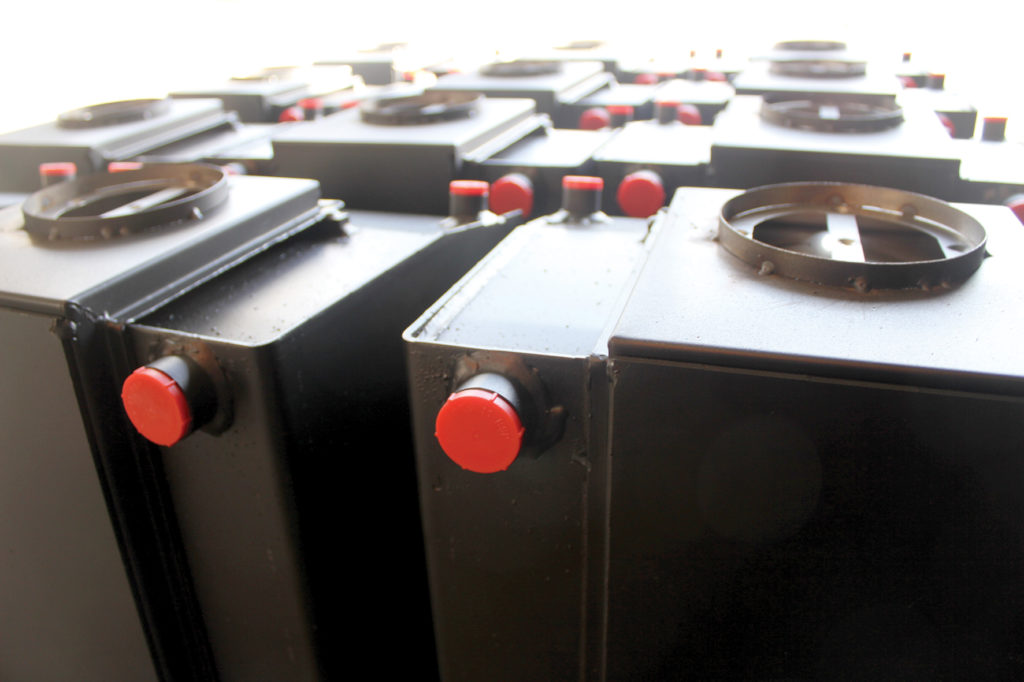

Heating solutions company Firebird is on an upward track: The company’s expansion since foundation in 1980 now sees it selling its boilers, solar thermal systems, biomass energy systems and domestic cookers in markets as diverse as France, New Zealand, USA, Germany, UK, Scandinavia and the Middle East.

Based near Macroom, Co Cork, Ireland, with distribution end sales in Co. Down and Devon. Firebird’s continuing growth has also seen it working with Ceramicx, another Co. Cork-based company, in order to create a bespoke system of heat work in its own factory; designed to help optimise the company’s evolving production needs.

For example, Firebird had a recent requirement to streamline and increase the throughput of its boiler production line. This was primarily needed in order to satisfy continuing demand and to circumvent seasonal bottlenecks for Firebird heating products.

The Issues

As part of the redesign of the workplace and the upskilling of production Firebird decided that the work of spray painting its boilers needed to be automated. The paint curing time on the sprayed boilers also then needed to be optimised in order that the products could be regularly shipped at a predictable rate. Paint curing time also needed to be freed from reliance on ambient temperature and weather conditions in order to help guarantee finished production.

After some careful research Firebird realized that the best and most effective heat source to use in these instances was Infrared heating. Not only was IR heating reckoned to be more cost-effective and cleaner energy than alternatives in gas or oil, the highly targeted nature of the infrared heat source and its transmission meant that a high degree of predictability could now be built into the Firebird production process.

The Solution

IR heating manufacturer and specialist Ceramicx was accordingly called to the table to assist in the design and build and supply of a new IR-based heating line for Firebird. The timing of this project also coincided with Firebird’s decision to use waterbased paints in its production process. The new IR heat process was therefore helpful in eliminating Firebird’s use of solvent-based paints; reducing VOC emissions and also reducing the carbon-footprint of the boilers generally.

After some initial assessment at the Firebird factory Ceramicx was commissioned to design and build:

- Firebird paint spray booth with IR heaters, extraction and control

- Firebird Infrared curing oven

Equipping the spray booth with IR pre heating was an important first step in helping the general paint adhesion and in preparing the products for the IR oven proper.

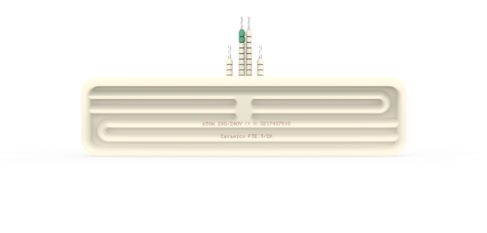

The new spray booth is a small steel-clad room; fabricated and fitted with infrared heaters modified from the Ceramicx industrial range. The booth has one air inlet and one outlet fan, lighting and a single control panel on the outside.

Firebird’s spray booth uses a paint-spraying robot and has a conveyor passing through it, carrying the unpainted boilers from the production area and then on into the curing oven. The robot paints the boilers as they index through the booth. After the spray booth the boilers enter the curing oven where they are moved into position according to the production programmes. The IR curing oven is heated to some 60°C and the dwell time in the oven is some ten minutes before visual inspection and end-of-line palletisation.

Firebird’s infrared curing oven heats and cures the painted surface of the boiler unit as it passes through on the conveyor. It does this using a combination of infrared and convection heating.

Ceramicx designed the Firebird oven to heat the target product primarily by infrared heat transmission, using radiant heaters mounted on the sides, top and lower area of the oven. The main infrared heating system is divided into 2 control zones: side heaters and top heaters. The bottom heaters are switched manually on and off if or when required. The infrared heating process is also assisted by a ceiling mounted extract air fan which helps reduce the humidity level inside the oven by removing warm, ‘damp’ air through the top of the oven.

For Ceramicx the Firebird project represents yet another successful instance of what it calls ‘applications engineering’; delivering bespoke and designed turnkey IR heating solutions for all kinds of manufacturers and industrial users. Ceramicx manufactures all the IR components and hardware itself and is thus able to guarantee smooth project management and competitive pricing.

Ceramicx sees the cost-effective potential of IR heating as largely untapped throughout the world: Not only are there multiple opportunities for IR heating lines in most manufacturing sectors, Ceramicx also believes that IR heat technology is also set to make great strides in the food, consumer, medical and healthcare sectors. Meantime Firebird production continues on its upward curve. IR heat solutions have helped the company with its automation and in increasing the throughput of its boilers through the system at a constant rate.

SUPPLIER – Ceramicx

CLIENT – Firebird Heating Solutions

BUSINESS – Boilers, Solar Thermal Systems, Biomass Energy Systems

LOCATION – Macroom, County Cork, Ireland