Case Study

Case study: Shortwave Infrared For Pre-Heat & Curing

With over 40 years’ experience, QS Group are national and international leaders in integrated automation engineering. Based in Cerreto d’Esi in eastern Italy, with manufacturing plants in Milan and Ancona, QS builds industrial components used by white goods manufacturers, together with systems and moulds for sheet metal, and plastic and foam processing.

Consistent pre-heat processes

QS has become renowned for their experience in industries including automotive, food, pharma, chemical, and mechanical over the years. But it’s their work in white goods manufacturing that is key to their success, helping them to expand their presence on a global scale.

As part of their component manufacturing procedures, QS relies on fast and consistent heat processes. Ceramicx’ long term relationship with QS Group, formed through another Italian heating company, has seen us deliver heating solutions to meet their needs, with standard or custom-made components to increase speed and efficiency to their operations.

In the past year, QS Group has increasingly turned to Ceramicx to manufacture shortwave custom-built pre-heat and various curing heating systems.

A larger custom heating system

QS needed a larger, custom-designed pre-heat oven system for the plastics division of their foaming plant. As leaders in their sector, QS Group’s experienced design and engineering team knew exactly what they required. Providing all their technical specifications in the supplied design drawings, the oven would achieve increased consistency in heating times, raising the temperature of two different materials by an increased speed of 20°C–30°C over the norm.

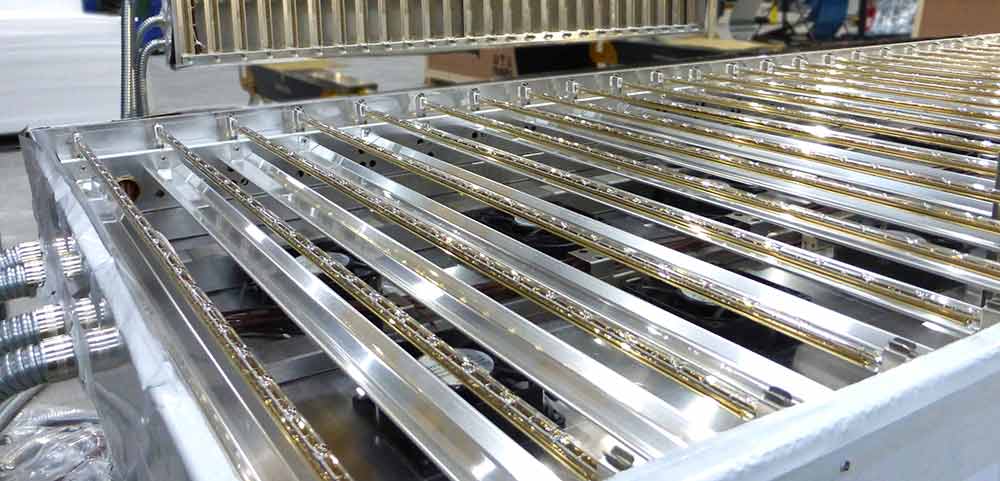

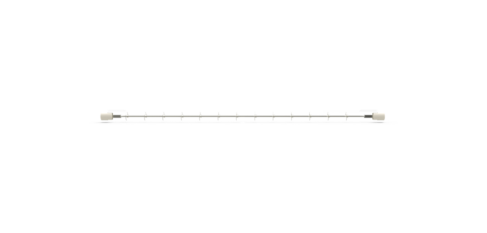

Knowing Ceramicx’ infrared technology capabilities, QS opted for an array of custom shortwave quartz halogen tube elements with 180° gold coating across two panels. The inclusion of custom aluminium clad steel reflectors would also maximise their radiant heat efficiency.

Our Ceramicx engineers then worked with the detailed drawings to custom-build the oven, with full production and manufacture scheduling, and testing, ready for QS Group’s final approval.

| Number of panels | 2 (upper and lower) |

| Power | 91kW per panel |

| Elements | Shortwave Quartz Halogen Tube / 3500W / 400v / 870/800mm / 180° gold coating |

| Element termination | FCB termination |

| Frame | Stainless Steel |

| Outer case | Aluminium |

| Electrical termination | 3 x 3m lengths of flexible metallic conduit |

| Weight | 120kg |

Standard and custom components

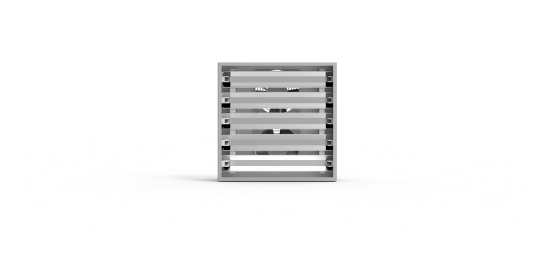

Together with custom-built pre-heat ovens, Ceramicx are also regular suppliers of infrared components to QS. Over the years, we’ve supplied – and continue to supply – custom and standard-sized infrared Fast IR system components for more efficient drying and curing processes.

Fitted with quartz halogen heater tubes as specified, the shortwave Fast IR assemblies ensure QS has the precision heat needed to cure bitumen-based noise dampeners for dishwasher production. We’ve supplied custom variations on our FAST IR 305 and FAST IR 500 products over the years for this very process.

The versatility of our products means QS and other customers know how flexible a Ceramicx infrared heating product is and how it can be used. Ceramicx are happy to work with QS Group, and other machine building customers, in the advancement of infrared heating technology for their processes and application.

If you think your process can be improved using shortwave assemblies please contact us and we can discuss applications with you.