Case Study

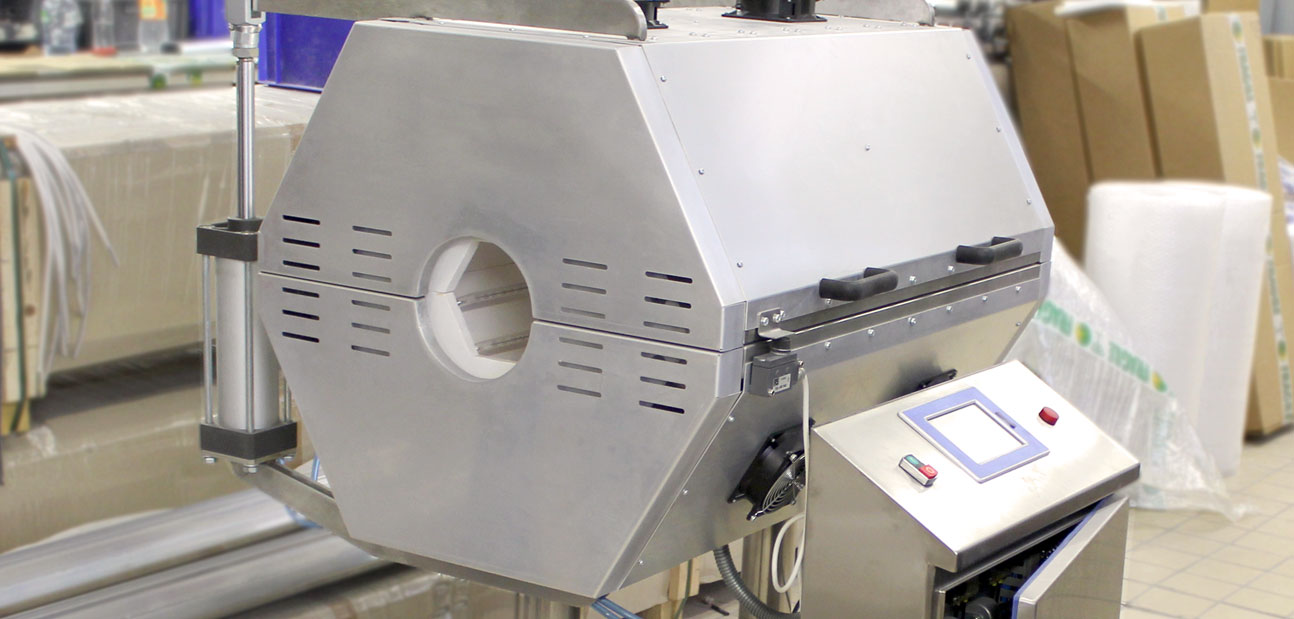

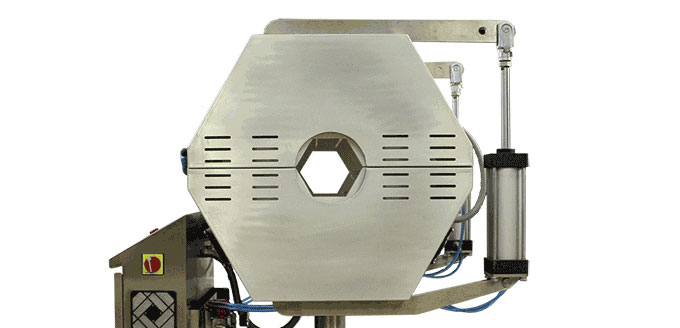

Case study: Clamshell Oven

Ceramicx industrial heat consultants not only provide solutions for custom infrared ovens. We have constructed a clam shell oven as part of our standard production offering. This 12KW+ unit is controlled through a HMI interface using control hardware and software from Cannon Automata and Ceramicx.

Fans and ventilation slits were used to keep the back of the insulation and wiring cool.

The oven shown in these images was bought via our US distributors Weco International. The clamshell shape was ideal for curing the outside layer of a synthetic material used in the drinks industry, where it was supplied to.

| Total Power | 12.1kW |

| Power supply | 3 x 400V + N + PE |

| Maximum current/phase | 18A |

| Maximum operating temp | 650°C ( 1292°F ) |

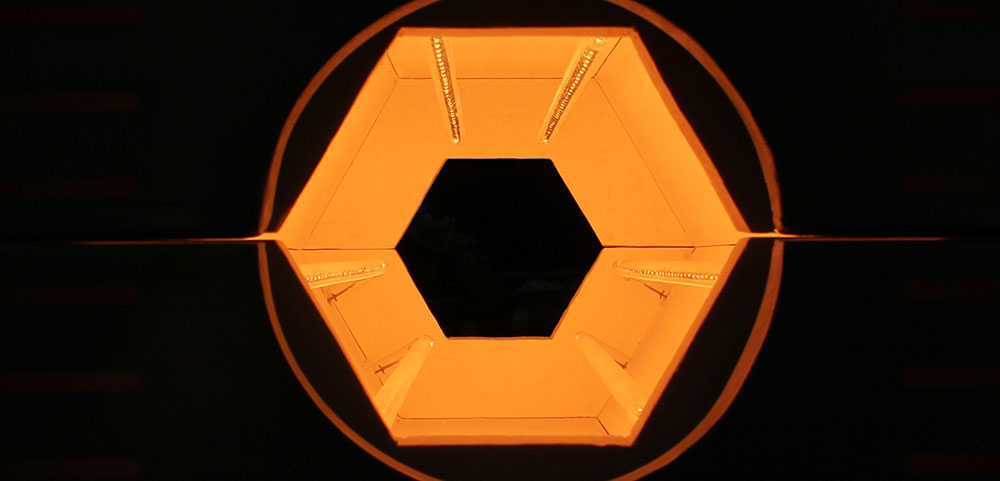

| Element type | Short wave quartz halogen |

| Control zones | 3 |

| Control type | 3 zone open loop (with optional single zone closed loop) |

| Control interface | Touchscreen HMI |

| Power control | Phase angle |

| Temperature measurement | Single type K thermocouple ( measuring air temp. ) |

| Footprint (oven closed) | 1153 x 991mm (45.4” x 39”) |

| Footprint (oven open) | 1400 x 991mm (55.1” x 39”) |

| Overall height (from floor) | 1350mm ( 53.1” ) |

| Oven length (entry to exit) | 991mm ( 39” ) |

| Effective heated length | 740mm ( 29.1” ) |

| Entry/exit Ø | 150mm ( 5.9” ) |

| Maximum product Ø | 100mm ( 3.9” ) |

| Approvals | CE |