Case Study

Case study: Portable Test Oven

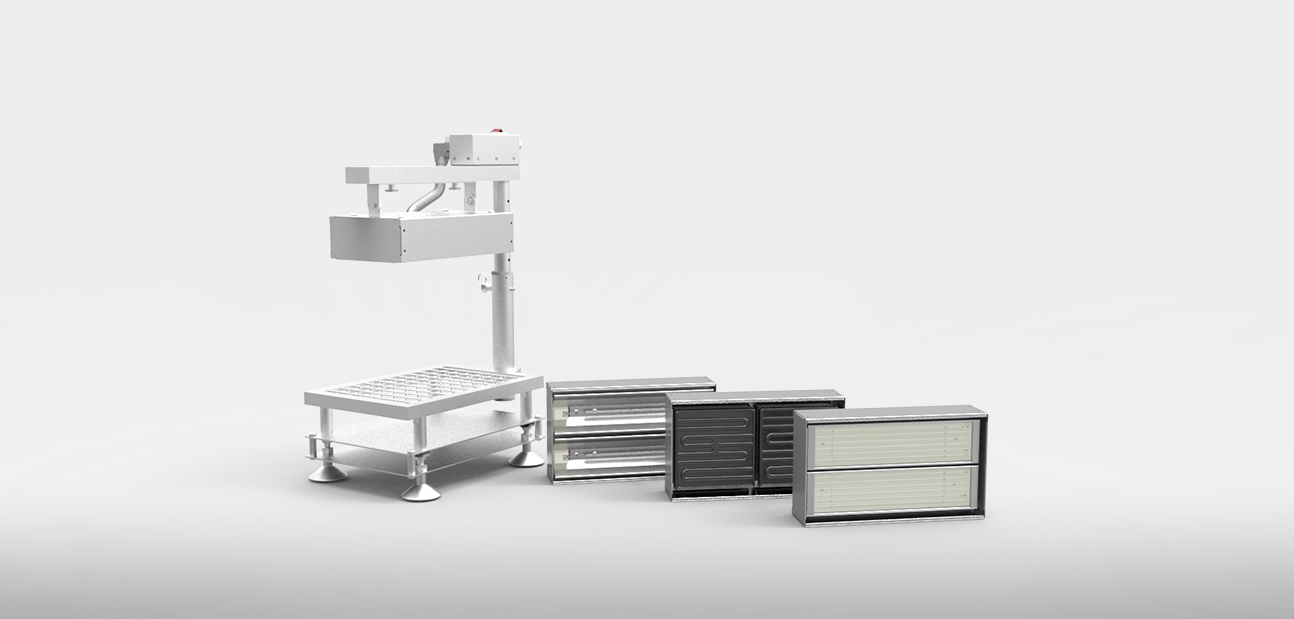

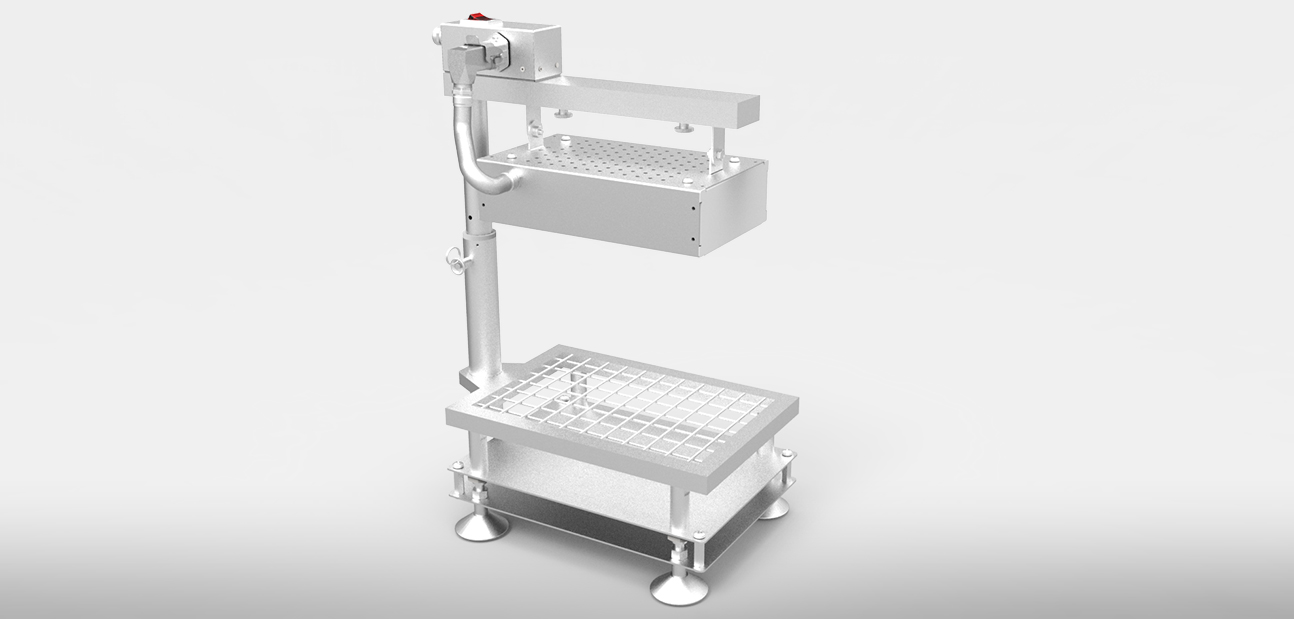

Ceramicx’ Portable Test Stand allows for quick and consistent testing of materials. Various long, medium, and short wave Infrared emitters are fitted in a modified PAS, which is easily attached to the test stand. The emitters face down and heat a material that is placed on a stainless steel mesh. The distance between emitter and material can easily be adjusted between 50mm and 200mm, in 50mm intervals. This test stand allows the user to quickly determine the most suitable type of emitter and heating distance for a specific material, with consistent results due to the simple, repeatable test set up.

Height adjustable test stand with fixed position material tray

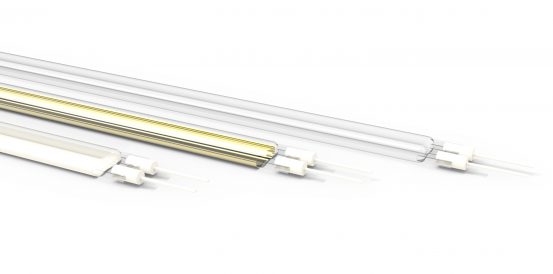

1.6 kW 230 V ceramic long wave heater assembly (Ceramic Element SFEH-800W)

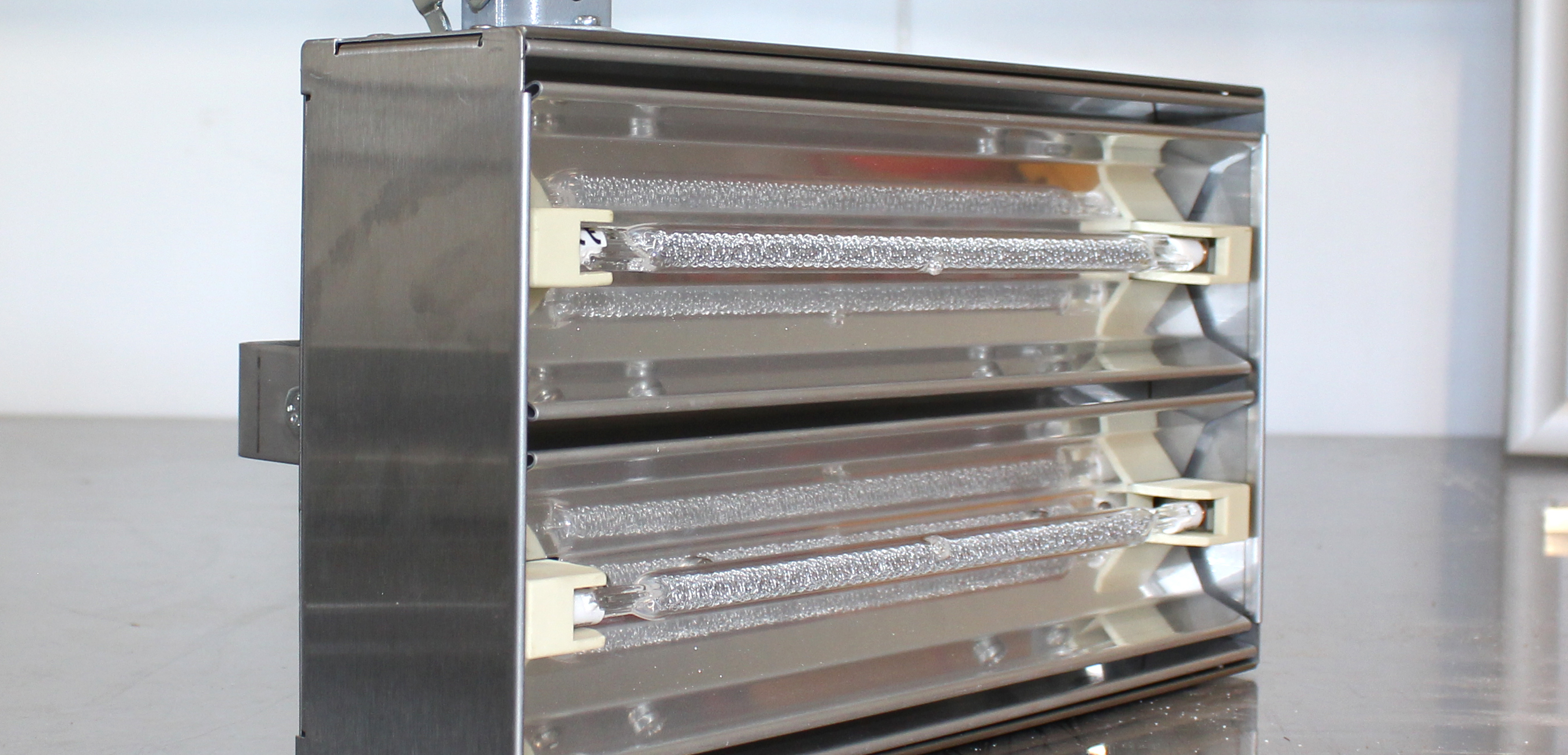

1.5 kW 230 V quartz medium wave heater assembly (Quartz elements FQE-750W)

1.5 kW 230 V tungsten heater assembly* (Tungsten tubes QTS-750W)

Fluke 62 MAX infrared thermometer

*Supplied with interchangeable element models:

-

- Fast medium wave QTS 750 W 240 V (x 2)

- Short wave QHS 750 W 240 V (x 2)