A comparison of the use of conventional heating and infra-red heating in out-of-autoclave curing of carbon fibre composites

There are currently a number of drawbacks relating to autoclave curing of carbon fibre composites. They are expensive to buy and operate, they limit component size, and slow cycle times hinder production volume. These factors among others have resulted in an increased focus on out of autoclave (OOA) methods in recent years, particularly within the aerospace industry.

The majority of OOA curing applications utilise convective heating. As the principle of a convective oven is to first heat the air, which in turn heats the composite component, difficulties arise when attempting to quickly and accurately alter the component temperature. It was proposed that these difficulties could be overcome using Infrared heating.

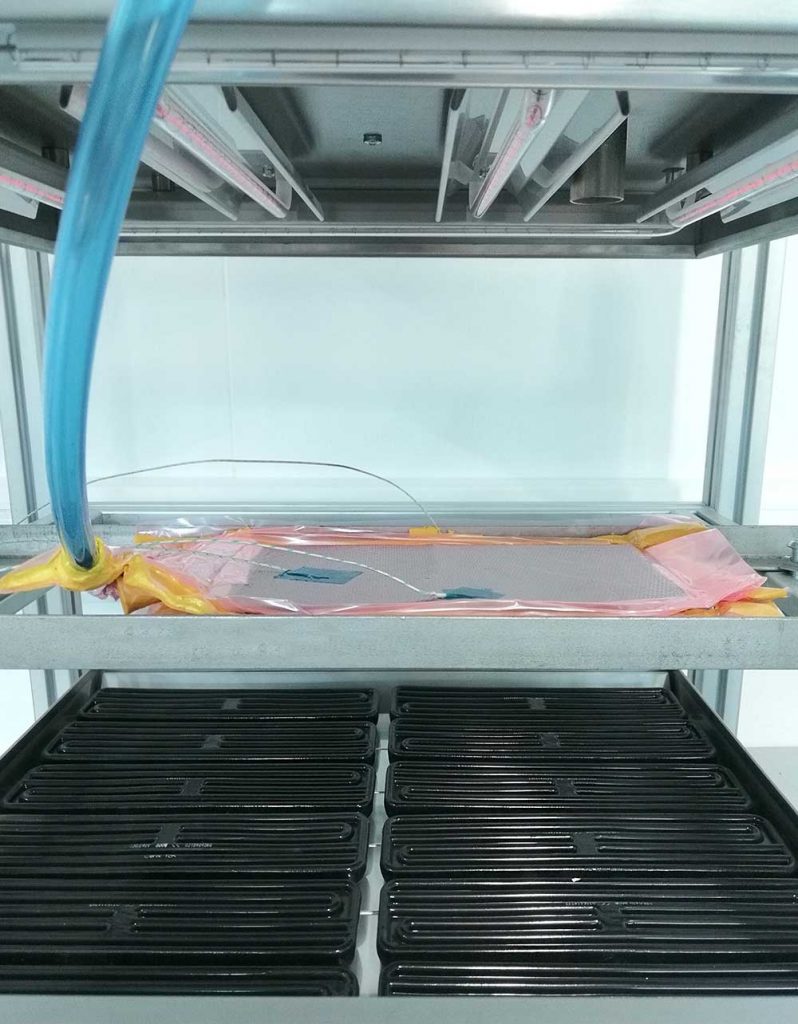

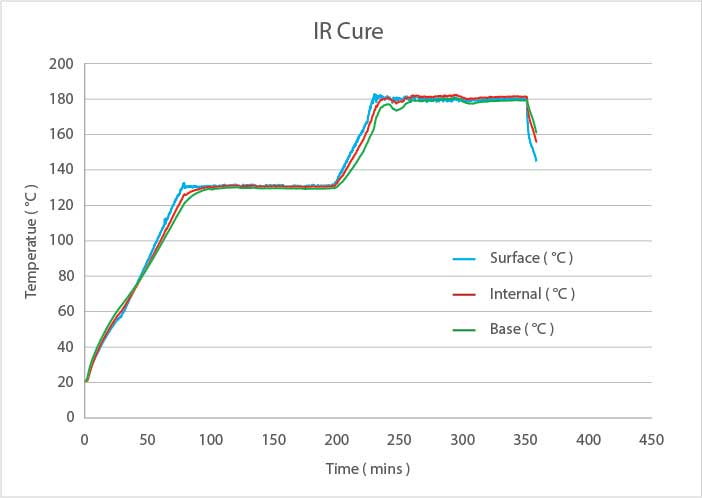

Ceramicx recently conducted a study to verify the benefits of using Infrared as opposed to convective heating in an OOA composite cure. The cured pieces were structurally tested post cure. The first major finding was the accuracy at which Infrared heating could maintain the desired component temperature in comparison to the convective heating, and the efficiency at which it could do this:

‘IR’s ability to respond rapidly to temperature variation ensures a greatly enhanced ability to match part temperature to intended temperature.’

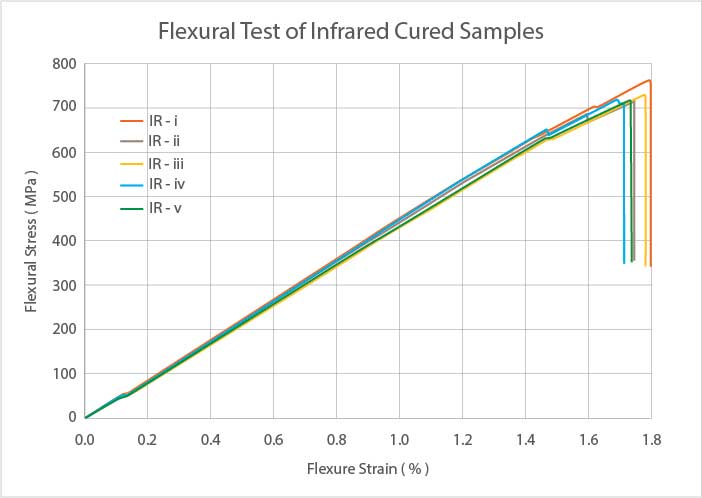

Samples were then structurally tested using Dynamic Mechanical Analysis (DMA) and flexural three point bending with the aim of gathering basic information to evaluate quality. It was found that the glass transition temperature attained through DMA testing was comparable, albeit a little lower on the IR samples: This was however due to an extended cure time associated with the convective sample which only further highlights the difficult nature of control.

Flexural strength was found to be higher on the IR samples than the convective samples due to the enhanced control of resin flow in the samples which is in turn controlled by accurate application of heat.

Our aim with this analysis was to establish baseline comparisons of curing methods and what we found was that we can very accurately control the curing of carbon fibre composites using IR.

To see the full report visit – ir-heat-experiments

See here for more information on glass temperature of various materials.