Application of infrared heat to materials

At the risk of stating the obvious, how much heat is applied for how long will depend on the process and materials.

Correct delivery and execution of infrared heating can support a considerable increase in production and efficiency. Approx 30% minimum.

Curing composites, forming and bonding automotive components, testing the heat shield on a spacecraft, drying concrete, thermoforming food packaging are just some of the applications that we have worked on recently. To learn more about these and other applications, please take a look at some of our infrared application customer case studies.

Choices of element type and use of reflectors

Selecting the appropriate infrared heating element and reflector types are key decision to be made when designing an efficient and productive heating solution.

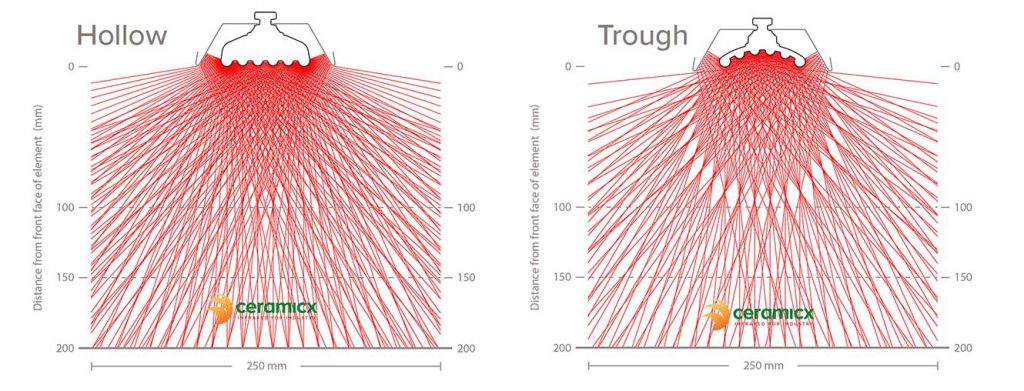

Below is an illustration of the radiant output of our ceramic element types.

At longer wavelengths, the amount of energy transferred will be lower due to the lower emitter temperatures, therefore heating times will usually take longer. The shorter the wavelength, the higher the emitter temperature and the available infrared power increases rapidly.

When selecting an infrared emitter for a particular heating task, the target material absorption characteristics are of high importance. Ideally, the emitted infrared frequencies and the target material absorption frequencies should match to allow the most efficient heat transfer.

There’s variation in the type of infrared heating that can be used in regard to the material. Some materials will absorb better using ceramic, some will require the high intensity of a halogen infrared heater, and some will require the medium intensity of a quartz type heater.

Infrared emitters used in industrial heating generally have a usable peak emission wavelength in the range of 0.75 to 10 μm. Within this range, there are three sub-divisions which are long, medium and short wave.

Longwave emitters, also known as far-infrared (FIR), have a peak emission range in the 3-10 μm range. This range generally refers to ceramic elements which consist of a high-temperature resistance alloy coil embedded into either a solid or hollow constructed highly emissive ceramic body. Ceramic emitters are manufactured in a number of industry-standard sizes with either flat or curved (trough style) emitting surfaces.

Shorter peak emission wavelengths are achieved by using emission sources with higher surface temperatures. Quartz cassette-style emitters are available in similar industry-standard sizes to that of ceramic and consist of a series of translucent quartz tubes built into a polished aluminised steel housing. These emitters can operate with higher front surface temperature and emit in the long to medium wave range.

At the shorter end of the medium wave range is the quartz tungsten emitter which consists of a sealed linear clear quartz tube containing a star design tungsten coil. The tungsten coil provides a fast response time with low thermal inertia.

The short wave quartz halogen range are of similar construction to that of the fast-medium wave tungsten emitter with the exception that a round tungsten coil is employed and quartz tubes are filled with halogen gas. The higher coil temperature results in the generation of white light and a peak emission wavelength in the short wave range.

Applying this information

Ceramicx offers the three types of infrared emitters and we can give you the reasoning behind our choices for each and every project. To learn more about the emitters Ceramicx use please see our elements explanation page.

Previous page: Types of heat transfer

Next page: The fundamental laws of Infrared heating