Case Study

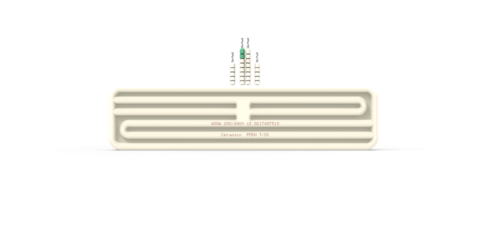

Case study: Vacuum Forming Oven

A major Canadian company that makes hot tubs, contacted our distributor in the United States to help them build one section of their machine. They were in process of building a machine to mould hot tubs and they wanted us to do the heat work for the section of their vacuum forming machine.

We specified the design of the heating system for them to fit into the space that they needed. They also needed additional design considerations as the oven had to ship in 2 sections due to the size of the overall oven. The two sections would then be assembled together in the customer’s facility.

The thermoforming ovens were then fitted into their machine, which went into their new fibreglass manufacturing process plant. They have since been running these ovens and have experienced some significant savings in both time and energy.

| Oven Type: | Forming Oven |

| Total Power: | 280 kW |

| Power Supply: | 3 x 480V + PE |

| Maximum Current/Phase: | 85A |

| Element Type: | Long Wave Ceramic FFEH Elements |

| Control channels: | 10 Zone Closed Loop |

| Total Size(per section) | 6.2m² |

| Approvals: | CE |