Case Study

Case study: Glass Forming Oven

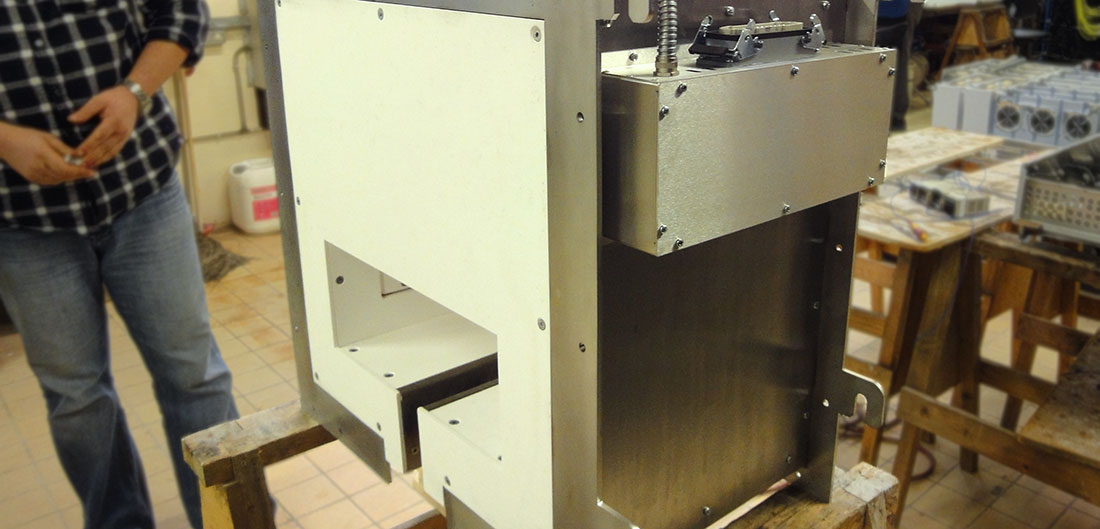

Ceramicx designed and built a single infrared oven heating module for a prominent customer in the United States glass industry. They wanted an R&D oven so that they could test whether they could heat up a specific glass, and afterwards form it so they could create a curve in the glass. This was so they could achieve more complex shapes of glass to be used for future assembly.

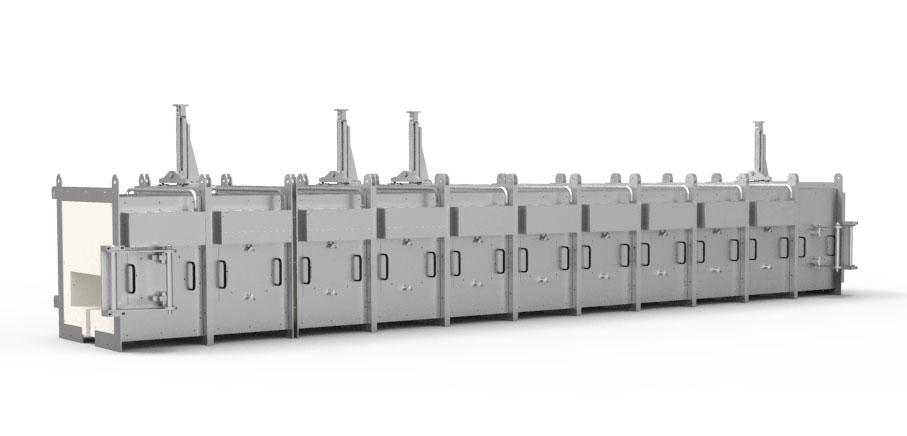

It was new territory for both Ceramicx and this customer. The process required precise temperature control, with a heat output of up to 900°C and very tight tolerances to ensure successful forming of the glass. Ceramicx developed a system consisting of nine heated modules and two access modules, installed in line to deliver the desired process temperature.

Each heated module contained specially designed fast medium tungsten heaters providing a total heat output of 11 kW per module. Target moulds were indexed through modules to provide the required heating curve.

To maintain tight temperature control and achieve the necessary forming conditions, the oven was built on-site using advanced insulative materials. This created a controlled thermal environment that allowed the glass to remain within specification throughout the process.

| Oven Frame: | Stainless Steel |

| Heater Type: | Quartz Tungsten tubes 1000W 240V |

| Length of 11 modules together: | 4.947m |

| Heat Output: | 11kW per module |

Once the oven modules were fully assembled, the customer traveled from the United States to our facility to conduct a successful Factory Acceptance Test (FAT). Following approval, the project was promptly shipped out.