Case Study

Case study: Test Equipment for Aerospace

Amba Projex, a client based out of the UK, approached Ceramicx to find a solution for their customer. The aerospace customer wanted some test equipment built to a small scale on a small budget just to see if they could get a result. Basically, they wanted to heat carbon material onto a metal drum to 150°C, and they wanted to only heat the material from the top of the drum. They wanted a single temperature controller and wanted a very lean price.

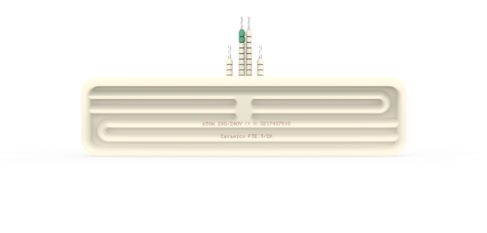

Ceramicx proposed a design that followed the curve of the drum using FTE heaters, this was to suit the design and the amount of material that the customer wanted to heat. The design included:

| Oven Frame: | Stainless Steel |

| Reflectors: | Polished aluminium clad steel |

| Element Type: | FTE 600W 230/240V |

| Zones | 1 Zone |

| Total Power: | Approximately 3 kW |

| Oven Size | 540mm x 270 |

| Controller: | KR1 controller |

| Control type: | Control Type Open loop or closed loop via pyrometer |

Ceramicx built the system end to end in 3 weeks after receipt of design approval and provided the customer with all the necessary drawings and documentation.