Case Study

Case study: Internal Curing of Aircraft Stringers

Ceramicx have developed a novel heating system for the curing of thermoset resins in the manufacture of composite aircraft stringers.

Background

Stringers are widely used in aerospace to increase stiffness in thin structures such as wings and fuselages while keeping weight to a minimum. An ‘omega’ or ‘hat’ is a common shape used in stringer design.

In composite structures, carbon fibre and epoxy resin are typically laid onto a male stringer cure tool, many of which are made from invar and then subjected to heat. There are a number of ways to achieve this finished structure:

- Stringer and skin cured in one shot

- Stringer cured separately and ‘co-cured’ to skin when skin is being cured

- Skin cured separately and ‘co-cured’ to stringer when stringer is being cured

- Skin and stringer cured separately and ‘co-bonded’ afterwards

As could be envisaged, there are advantages and disadvantages of all approaches but from the perspective of reducing cycle time, manufacturing everything in one shot is the most favourable option. One complexity arising in pursuit of this approach is even heating. Autoclaves or out-of-autoclave (OOA) ovens that use convective heat are standard for this. However, if we analyse such a structure, it can be seen that geometrical thickness can vary considerably in locations; for example, in the unsupported region, there is just the skin itself and around the stringer, there is the skin thickness + stringer thickness. If such a product is being placed in a convection oven at a set temperature, it is very clear that there will be considerable variation in the temperature profile at areas of differing thickness. As the cure creates the physical properties of the finished part, even heating is essential.

The RAT Internal Curing System

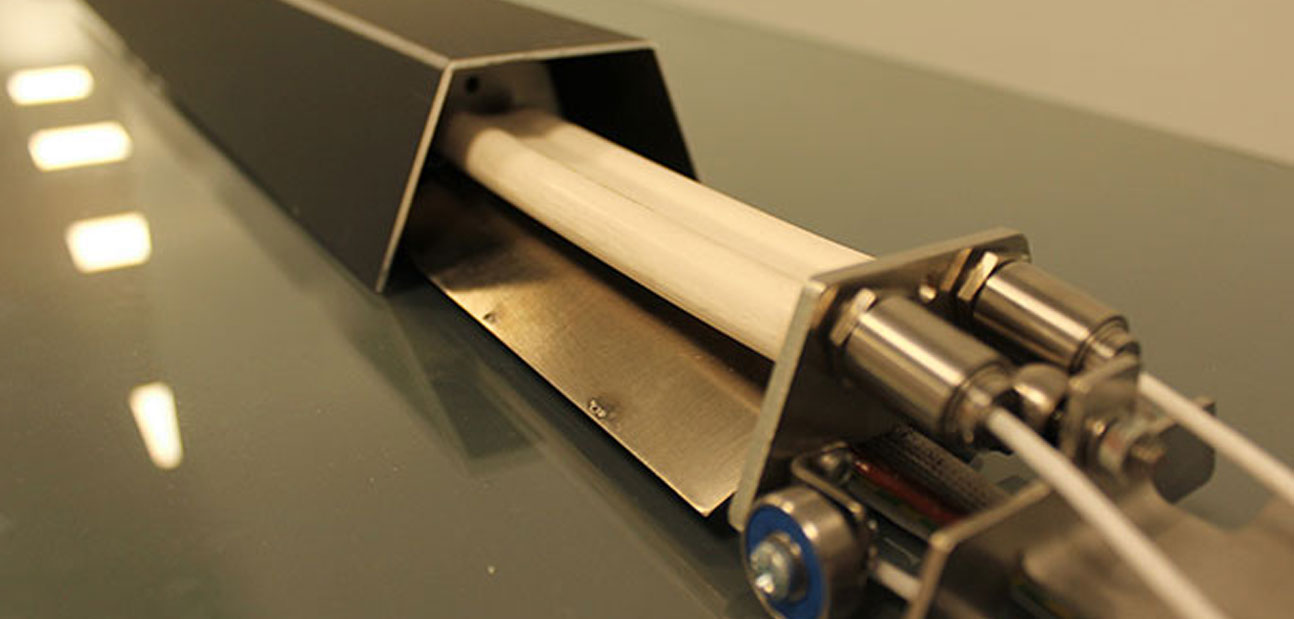

Ceramicx’s RAT is a range of products that travel up inside enclosed structures and heat them from the inside out. It can drive or be pulled through curved profiles and although it’s potential across many industries is widespread, the RAT was developed primarily for out of autoclave (OOA) curing of composite stringers. The RAT is a low-profile InfraRed (IR) emitter, with specially designed reflectors that travels up inside the stringer tool and cures the stringer from the inside out.

The development of the RAT means that even heating of the stringer and skin can now be achieved in one curing operation. The drawbacks of curing in a conventional oven have been documented extensively in the past but can be greatly reduced with this approach. When combined with Ceramicx’s under-tool heating systems in traditional egg-box tool designs or with bespoke overhead IR curing systems, the potential benefits are significant. The system can also be modified for use with resin infusion and for consolidation of thermoplastic composites.

For approaches where stringers are cured separately from the skin, the RAT offers the potential for no tool movement to curing ovens, no excessive energy usage from convection curing systems and no potential bottlenecks associated with the oven thus considerably reducing cost.

The long wave custom shape element was design and manufactured in house. Ceramicx delivered the temperature measurement proposal despite the size and heating challenge that was presented.

Further Applications

Although primarily for curing of stringers, the RAT can also be used for curing of filament wound vessels and tubes, curing of underground drainage liners and forming of thermoplastic composites.