- About

- Heating Solutions

-

-

- Heating Solutions

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghai in East China ... Read moreChinaplas 2025

-

-

- Industries

- Enquiries

- Contact us

- Ceramicx Components

Industrial Infrared Heating Solutions

Home Heating Solutions

For specialist applications and materials testing, Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

Drawing on a wealth of in-house knowledge and experience in application engineering and heatwork development, each oven is built to precise customer requirements. Each oven or system can be produced to sit within any existing frameworks or as complete, standalone systems capable of integrating into other machinery.

The choice of short, medium, or long wavelengths for any custom oven or heating system will be dependant on your chosen application process. The installed power is always specified to our rule of ‘as much as necessary, as little as possible’.

We also keep the entire infrared process under one roof. That way, we’re able to give you an end to end service that takes care of your own unique oven, from modular, precision solutions to custom-built, high temperature ovens for specialist testing.

These case studies are examples of what we have done in the past to give you a better idea of what we can do for you. See our Infrared Solutions Case Studies Guide also.

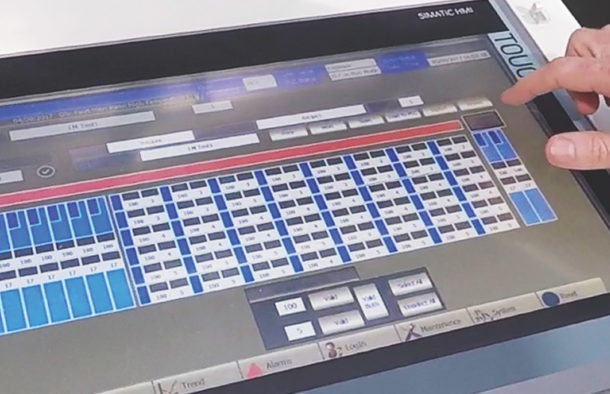

Control systems

By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

Read more

FILTER SOLUTIONS

-

Case Study: Carbon Fiber Heating System For Aerospace

Learn moreAs an independent, national centre for the world-class design and manufacture of composites, our client’s testing production capabilities were already meeting multi-sector demands.

-

Composite Pre-Heat Oven

Learn moreA UK based company specialising in the coating and laminating of complex textiles, and cutting of carbon composite materials, had issues with processing their materials which due to their nature needed very accurate control.

-

Four Column Vertical Curing System

Learn moreTo heat four separate, composite parts, vertical heater columns were fitted with 22 infrared emitters and 3 pyrometers for precise, non-contact temperature measurement at 1” increments along the material.

-

Long Wave Composite Curing Oven

Learn moreCeramicx developed a composite curing oven, which was embedded in a robotic press cell for a variety of composite systems.

-

Modular Long-Wave Infrared Heaters In Composite Curing

Learn moreCeramicx SFEH black ceramic heating elements provided the higher temperatures required to fuse the materials, leading to faster curing times. Our inhouse Ceramicx team were then able to draw up drawings for a unique heating system, based on our own Modular IR 260 infrared technology.

We look forward to hearing from you

Get in touch with one of our infrared heating experts