Case Study

Case Study: Carbon Fiber Heating System For Aerospace

As an independent, national centre for the world-class design and manufacture of composites, our client’s testing production capabilities were already meeting multi-sector demands. With the growth of dry fabric infusion in the aerospace industry, they now needed an innovative solution to increase composite testing, offer significant savings, and set new industry benchmarks.

The Challenge

Our client has brought together both companies and academics to develop new technologies for the design and manufacture of high-quality composite products. With state of the art facilities, they’re leading the coordination of a network of regional centres of excellence in the UK composites industry.

In the industry, there has been a move away from traditional prepreg and autoclaves, to dry fabric infusion. An essential step in infusing dry fabrics is ‘pre-forming’ – a process using heat to activate a binder in the dry fabric to produce a semi-structural ‘pre-form’. This method has seen increasing growth in aerospace structures, specifically in the manufacture of stringers, the structural supports within an aircraft wing that prevents buckling and bending under compression.

The Search For Solutions

As an industry leader in the design and manufacture of infrared heating systems, Ceramicx have developed an extensive knowledge of the aerospace industry, with the necessary experience of heating composite products, including the curing of thermoset resins.

Working closely with our client, Frank Wilson, Managing Director here at Ceramicx, comments, “When undertaking a project of this nature, we always understand the specific requirements of the process. Geometry, nature of the control, anticipated processing speeds, and budget all play a big part in the formation of a bespoke solution”.

With infrared offering consistent and notable advantages over traditional convection ovens, we demonstrated how infrared can offer significant savings in the heating of stringers during the ‘pre-forming’ process, and how a bespoke control and system design would prove crucial to our client’s success.

The Implementation

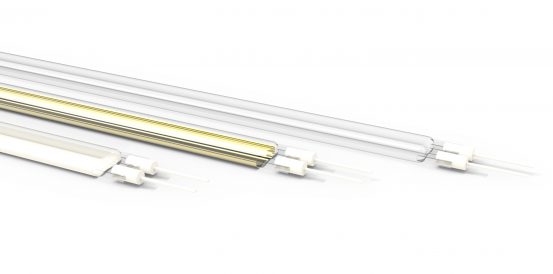

Following a process of further research and development, our designs and plans were approved. We then custom-built the IR oven and its own 12-zone heat control system–optimising the oven for efficiency and appropriate processing parameters–all to the client’s specifications. The trapezoid shape created by the reflectors matches the composite pre form shape.

Fast-response, quartz halogen heaters were chosen for their emitter type due to the extensive data generated by Ceramicx with them for heating carbon composite materials. Their geometric and relative arrangement was based on extensive R&D of heating composites to give the best performance. By easily selecting and deselecting relevant zones, the oven provides adjustability for different stringer shapes and lengths.

| Total Power: | 56.8 kW |

| Heaters | Custom Quartz Halogen tubes (400W x 20 pcs, 850W x 24 pcs) |

| Zones | 6 |

| Electrical Circuits | 2 per zone |

| Pyrometer | 6 x pyrometer CT -SF 15, one per zone |

The Result

The result of this infrared oven is a process that is 3 to 4 times faster than that of a convection oven, with a much smaller footprint and the ability to move the oven to the workpiece. That in itself has made significant energy savings. The heating arrangement has been optimised to set an industry benchmark in the through-thickness heating of composite structures.