Case Study

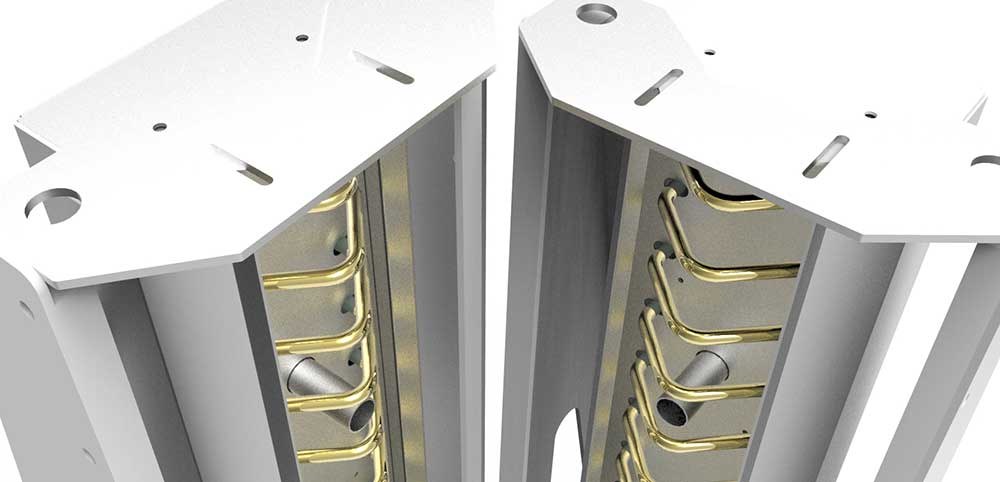

Case study: Four Column Vertical Curing System

As a global sector, the aerospace and defence industry relies on technical accuracy in every aspect of production. In every production process, heat plays a major role, and maintaining a precise temperature is vital to achieving the high level of product quality required.

Ceramicx Custom Heating System

To meet our aerospace, defence, and security client’s requirements, our custom-designed, 22kW heating system needed the capability to precision cure composite materials. Producing temperatures of between 100 – 360°F (37 – 182°C) with a 365°F (185°C) fail safe shut-off, the system features 12 control zones, incorporating 88 quartz halogen tubes (250W / 240V) with polished aluminium reflectors.

To heat four separate, composite parts, vertical heater columns were fitted with 22 infrared emitters and 3 pyrometers for precise, non-contact temperature measurement at 1” increments along the material. With an in-built display countdown for curing time, the system also notifies the system users when the cure profile is complete.

With every custom heating system project like this, Ceramicx always integrates a heating control system, providing every project and customer with a complete heating and control solution. This project was no different. By integrating a Siemens SIPLUS HCS4200 control system, the client would have absolute precision temperature control.

| Total power | 22kW |

| Frame | SS304 |

| Element Type | Special quartz halogen heater 250W 240V (x88) (180o gold reflective coating) |

| Reflectors | Polished aluminium clad steel |

| Control Zones | 12 |

| Power Control | Siemens HCS 4200 system |

Precision Temperature Control

Siemens, in developing their SIPLUS HCS systems for industrial heating applications, has perfected a range of flexible, and modular heating control systems. Depending on the requirements of the heating process, each has the capability to activate and switch between industry-standard infrared heating elements for precision heat wherever it’s needed.

Classed as ‘the flexible solution’, the SIPLUS HCS4200 is a control system featuring different output modules, I/O modules, and racks. Used for any compact or modular concepts with low to medium levels of power output, the HCS4200 provides precision control for heating elements up to 20A at different voltages. Together with integral voltage diagnostics for detecting internal and external faults such as tripped fuses or wire breaks, intelligent and detailed diagnosis of heating elements, and quick installation with reduced cabling work, the HCS4200 was the ideal cost-effective heating control solution for their requirements.