Case Study

Case study: Composite Pre-Heat Oven

A UK based company specialising in the coating and laminating of complex textiles, and cutting of carbon composite materials, had issues with processing their materials which, due to their nature, needed very accurate control.

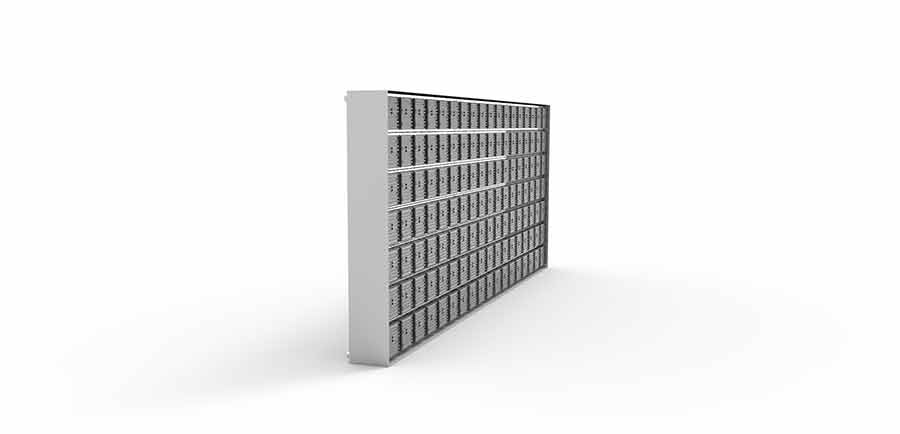

Ceramicx designed and built the heating system with 4 zones so that the infrared energy was transferred evenly. The overall dimensions were set by the customer but it was Ceramicx’s decision to use the SFEH elements, which were best suited to supply the heat required.

This oven allowed the customer to pre-heat their composite materials, allowing them to process their materials more easily. The materials absorbed the infrared energy best from the SFEH black element. It provided significantly better results than any of the other systems. Finally, the ease of which the width can be changed by selecting and deselecting zones was a key aid to the customer.

| Total Power: | 75.6 kW |

| Power Supply: | 3 x 400V + N + PE |

| Maximum Current/Phase: | 85A |

| Element Type: | Long Wave Ceramic SFEH 600W 480V Elements |

| Total Heating Power: | 70kW |

| Control channels: | 4 Zone Closed Loop |

| Controller: | Ascon KR1 |

| Footprint: | 2.5m x 1m |

| Approvals: | CE |