Case Study

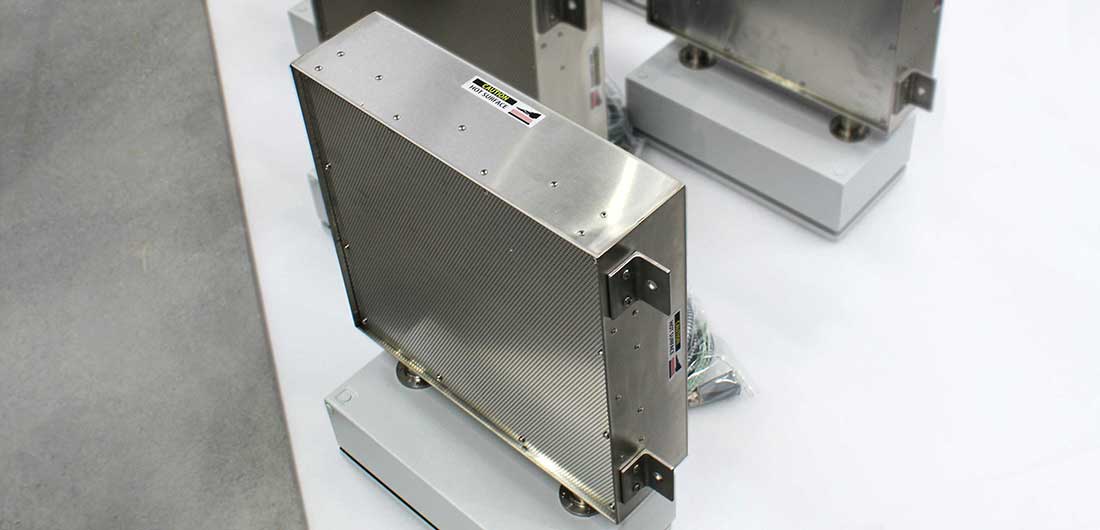

Case study: Quartz Infrared Heating Modules

These modules were manufactured for a global sports brand manufacturer.

Ceramicx manufactured and assembled these modules in house using Ceramicx PHQE elements (Pillared Half Quartz Element). They were each pre-wired to specifications given. The perforated back cover is perforated as Ceramicx standard to ventilate the wring area. Each element included a thermocouple connection for precise temperature monitoring.

| Module Power | 3.75kW |

| Element Type | PHQE 250W 230V TcK x 15 |

| Overall Dimensions | 590mm x 475mm x 200mm |

| Reflectors | Polished aluminium clad steel |

| Back Cover | (Removable) manufactured from perforated aluminium sheet |

| Frame, brackets, and side wall | Stainless steel 304 |

| Electrical Connection | Via junction box with M16 x 3m flexible metallic conduit |