- About

- Heating Solutions

-

-

- Heating Solutions

- Ceramicx has the in-house capabilities to build custom-designed industrial infrared ovens and heating solutions to almost any design and specification.

-

- Control Systems

- By providing customised controls to suit specific heating applications, Ceramicx offer control solutions that meet every requirement.

-

-

-

- Retrofits, Rebuilds & Upgrades

- Information

-

-

-

Latest Blog

Chinaplas 2025

Chinaplas is an annual exhibition for the plastics and rubber industries which rotates location annually, between Shanghai in East China ... Read moreChinaplas 2025

-

-

- Industries

- Enquiries

- Contact us

- Ceramicx Components

Specialised Infrared Ovens

Home Heating Solutions Oven Process Specialised Infrared Ovens

Ceramicx industrial infrared specialised ovens are fully customised to the individual materials, process parameters, and characteristics required for uniform heating in niche applications.

Whether these ovens are designed as standalone equipment or integrated into a further macro industrial process, due to our in-house manufacturing resources, Ceramicx can design an oven to fit your needs. By having so many in-house capabilities, we have the flexibility to approach a project differently to other companies that outsource or only produce standard heating systems.

Ceramicx specialised ovens provide exceptional results for extreme and precision infrared heatwork for specified processes. Designed by our engineers, every specialised oven is custom-built and manufactured to meet your own specifications and standards, for use across multiple industries.

Using our full product offering of Ceramicx infrared heating elements installed as standard, specialised ovens can be designed for large or small volume applications. Together with custom temperature ranges, physical size, and custom configurations all meeting your requirements, a specialised infrared oven will give you optimal energy-efficiency and output.

All Ceramicx specialised ovens are designed and built bespoke by our engineers and fully customised to your specifications. Manufactured using a stainless steel framework with specialist insulation and aluminium clad steel reflectors, your oven is built to include multiple heat zones with custom heater geometry to accommodate your chosen infrared element type.

Using Ceramicx, CE approved infrared radiant heating elements to suit your processes, each oven can feature complete and bespoke custom controls for precision heating tolerance in °C, thermocouple monitoring, and element failure detection. But your own safety features can also be built-in, including emergency stop features and safe to touch areas.

A quality-assured Ceramicx specialised infrared oven will give you energy and cost-efficiency with increased accuracy and productivity, and can also include:

-

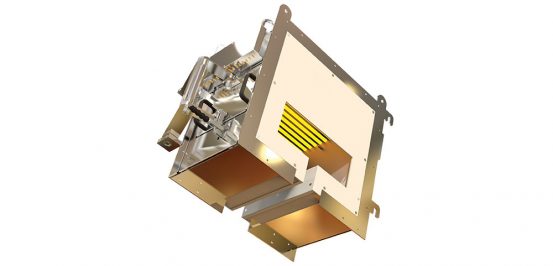

Aerospace Industrial R&D Furnace Oven

Learn moreWeco International, our business partner in the United States introduced us to the client, a private aerospace manufacturer that provides spaceflight services. The client needed a heating system that could replicate the conditions of atmospheric re-entry in a controlled setting.

-

Bonding Automotive Interiors

Learn moreOne of the biggest US automotive companies were looking for a more automated solution to their production process. Their Tier 1 supplier made contact with our business partner in the United States, Weco International.

-

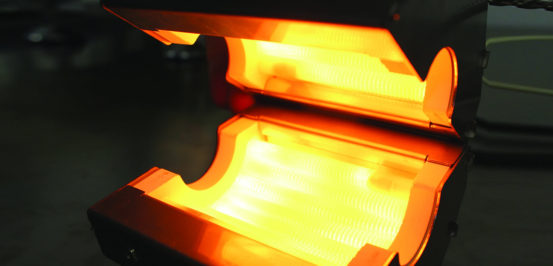

Contract Manufacturing: Heatshrink Application

Learn moreWith two infrared heat solutions needed, both had strict specifications in terms of power, temperature, dimensions, and reliability, and both were developed using our infrared quartz heating elements. The clamshell shape was a natural consideration and Ceramicx worked on this using quartz infrared elements components.

-

Custom Infrared Oven For Injection Mould Tooling Manufacturer

Learn moreThe principal feature of this oven is the inclusion of 16 custom-made, 10kW, shortwave, twin-tube quartz halogen infrared elements controlled via open-loop technology, giving each heater its own individual zone. The oven also includes a pneumatically operated door mechanism with vertical operation.

-

Four Column Vertical Curing System

Learn moreTo heat four separate, composite parts, vertical heater columns were fitted with 22 infrared emitters and 3 pyrometers for precise, non-contact temperature measurement at 1” increments along the material.

-

Glass Forming Oven

Learn moreCeramicx designed and built a single oven heating module for a prominent customer in the United States glass industry.

-

Internal Curing of Aircraft Stringers

Learn moreCeramicx have developed a novel heating system for the curing of thermoset resins in the manufacture of composite aircraft stringers.

-

Quartz Infrared Heating Modules

Learn moreCeramicx designed and manufactured the modules in house using Ceramicx PHQE elements (Pillared Half Quartz Element).

Bespoke manufacture, design and build

- Mounting brackets and wheels for easy lifting and moving

- Extra structural protection and features for easy shipping and partial re-assembly

- Specialist insulation, steel meshing, rotary wheels, and viewing windows

- Multiple doors for easy access to heat chamber

- Custom safety features for your process needs together with emergency stop

- Bespoke electrical junction boxes positioning

- Custom venting or extraction systems

- Full range of spare parts

Bespoke heating system and controls

- Material testing for your process

- Quartz elements or Quartz Halogen or Quartz Tungsten or Ceramic tube heaters to suit

- Modified Fast IR and Modular IRs

- Upper, lower, and vertical heating panel systems with adjustable height

- Custom heater geometry and multi-zoning with concentration of heat direction

- Custom distance and heater array

- Remote monitoring capabilities

- Complete individual custom programme control or modular system

- Element failure detection option

- Precision heating tolerance in °C/ºF

Whatever configuration you require for your specialised oven or heating system, our specialist heat engineers will custom design and build a complete and bespoke infrared heating system to your specifications. Our full ‘Project Completion’ approach gives you a comprehensive end to end service that keeps you updated through every stage of the process.

After your initial enquiry and our detailed proposal, we can provide detailed photos of progress if required – from materials testing and R&D to the functional design specification (FDS) and 3D CAD/CAM design, to product testing and final manufacture.

Solution Testing

This is your system, designed and built by us to your specifications and we undertake detailed and thorough system testing at every stage. Our ceramic and quartz infrared heating elements have detailed end of line test results and performance data to confirm correct operation.

YOUR NEXT STEPS

At Ceramicx, we have the in-house capabilities to build custom industrial infrared ovens and heating solutions to almost any design and specification. Whatever your requirements, we’ll give you the clarity and advice you need to design and build a high quality, infrared heating solution that meets your needs.

Call our technical team today on +353 28 37510 or email on [email protected]. We’ll be more than happy to discuss potential solutions and answer all your questions so you can make an informed decision.

We look forward to hearing from you

Get in touch with one of our infrared heating experts