Bespoke infrared heating solutions for aerospace & defence

Ceramicx has huge experience in working in aerospace & defence industries and has successfully completed several projects where infrared heating has been used to form lightweight aerospace components and substructures.

In addition, we’ve worked with our partners to design, manufacture, and complete test ovens for the aerospace industry, enabling them to further test materials and components needed for production.

The advantages of infrared as a heat source allow aerospace engineers to effectively target a structure and component with the required level of heat which can be easily and accurately monitored to ensure process quality and accuracy.

We’ve also worked on specialist heat simulation and heat testing projects for leading OEMs in the aerospace industries. The failsafe requirements needed in this sector mean the heat performance of all new aircraft designs, including engines, fuselage, and other critical components, must be 100% guaranteed fit for purpose.

Infrared heat engineering has a full role to play in this industry and Ceramicx is leading the way.

Learn about some infrared heating solutions for the Aerospace & Defence industry that we have developed –

-

Aerospace Industrial R&D Furnace Oven

Learn moreWeco International, our business partner in the United States introduced us to the client, a private aerospace manufacturer that provides spaceflight services. The client needed a heating system that could replicate the conditions of atmospheric re-entry in a controlled setting.

-

Case Study: Carbon Fiber Heating System For Aerospace

Learn moreAs an independent, national centre for the world-class design and manufacture of composites, our client’s testing production capabilities were already meeting multi-sector demands.

-

Four Column Vertical Curing System

Learn moreTo heat four separate, composite parts, vertical heater columns were fitted with 22 infrared emitters and 3 pyrometers for precise, non-contact temperature measurement at 1” increments along the material.

-

Internal Curing of Aircraft Stringers

Learn moreCeramicx have developed a novel heating system for the curing of thermoset resins in the manufacture of composite aircraft stringers.

-

Long Wave Composite Curing Oven

Learn moreCeramicx developed a composite curing oven, which was embedded in a robotic press cell for a variety of composite systems.

-

Quartz And Ceramic Infrared Heating Systems For OEM Industry Leader

Learn moreUsing a mix of quartz and ceramic trough infrared elements, the new stand alone IR systems would bring efficiency and speed to their processes.

-

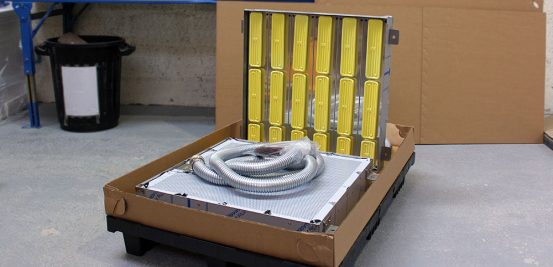

Test Equipment for Aerospace

Learn moreThe aerospace customer wanted some test equipment built to a small scale on a small budget just to see if they could get a result.