All our case studies in one publication – Ceramicx Infrared Solutions Case Studies Guide.

Ceramicx infrared solutions

Ceramicx manufacture and supply infrared products and components to over 80 countries globally.

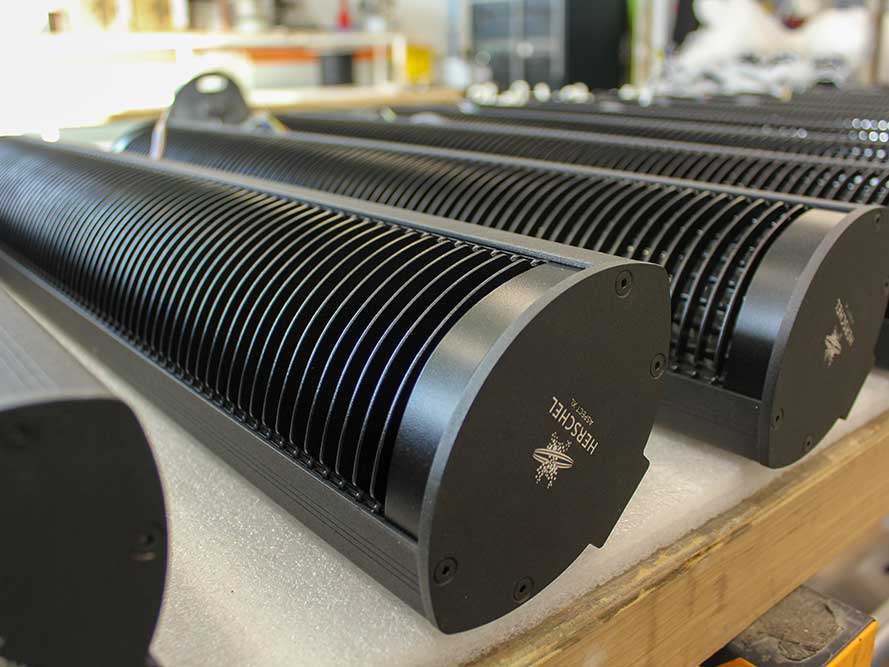

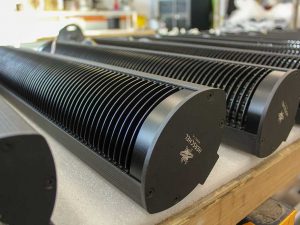

We are also a leading manufacturer of custom-built infrared industrial heating ovens, heating systems, and solutions. It’s the solving of our customers infrared applications engineering difficulties where our knowledge and expertise are invaluable.

The combined knowledge, experience, and expertise of our engineering team means Ceramicx are capable of designing and custom-building a range of infrared solutions for any industry or sector. From infrared heaters for thermoforming to custom infrared ovens, infrared panel heaters, and heaters for industrial processing.

We keep everything under one roof too. So if you have a unique problem with the application of heat to an industrial process or product, we can design and build the heater and the solution in-house, from start to finish.

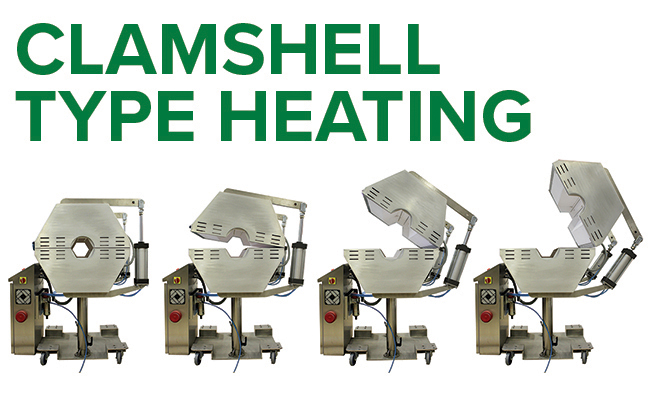

Industrial Ovens

Through all our experience, we’ve built up the resources in applications engineering and heatwork development to custom-design and build industrial ovens to meet every customer’s needs. Your choice of oven and its abilities will always be material and process dependant, but whether it’s short, medium, or long wave infrared heat, we’ll design an oven and control system that meets your individual requirements.

Processes

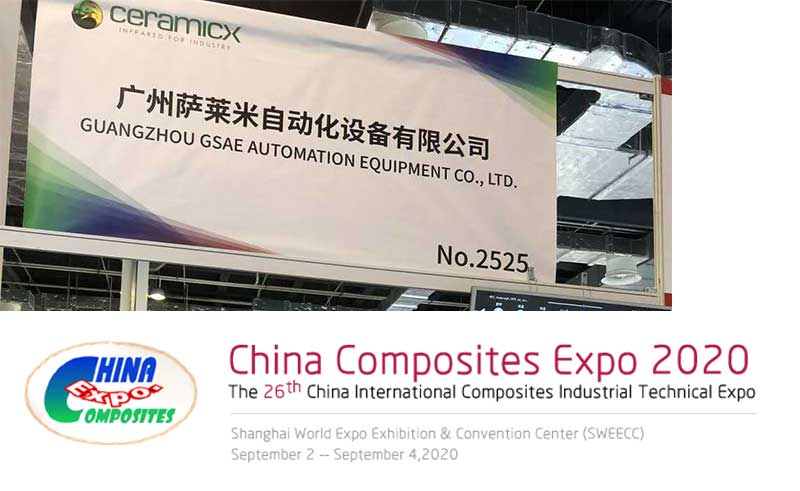

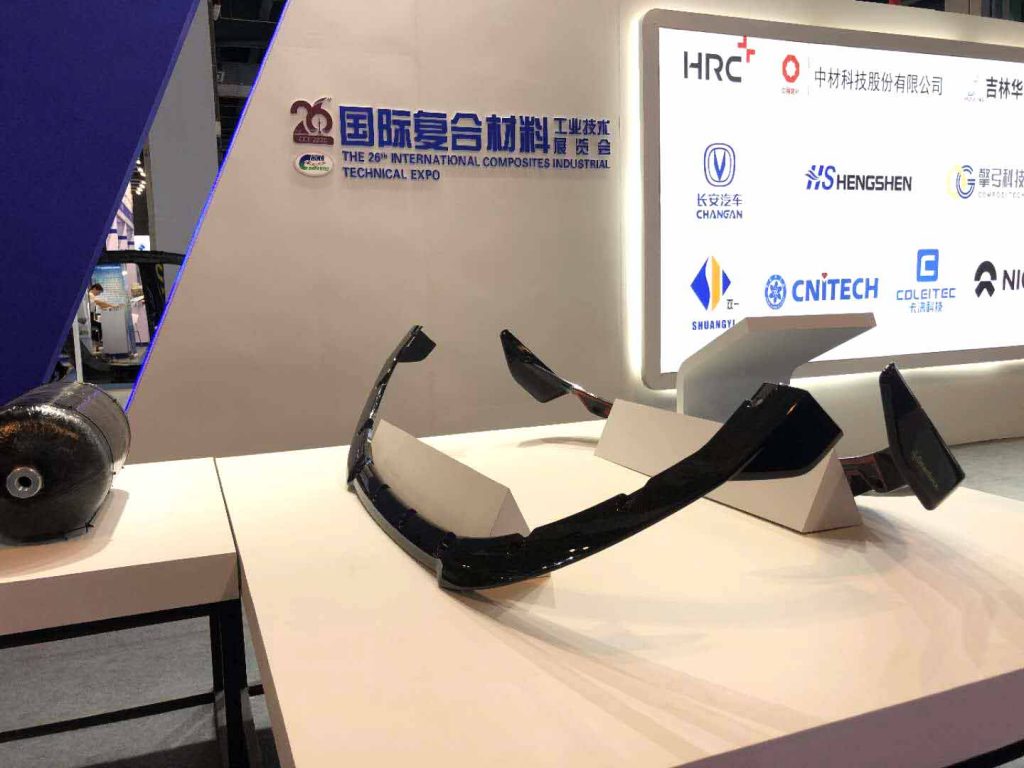

Infrared is a cost effective and energy-efficient method of heat application and is used in multiple processes, industries and manufacturing sectors around the world. From the curing and thermoforming of composites and plastics to the drying and curing of paints, polymers, and inks, Ceramicx infrared heating technology is key to designing, developing, and building a custom system that provides controlled accurate and zoned-temperature control.

Industries

Working with many different industries, our engineered, infrared application solutions are built for a wide variety of applications and processes. Our custom heating ovens and control systems are used extensively across the aerospace, automotive, construction, and packing industries.

As the world’s leading quality management standard, the ISO 9000 system is used by thousands of businesses and organisations in over 170 countries, whatever their size or sector. By gaining full ISO 9001:2015 certification for our Quality Management System (QMS), Ceramicx can focus on increasing our performance and productivity while taking the next step as infrared industry leaders.

As the world’s leading quality management standard, the ISO 9000 system is used by thousands of businesses and organisations in over 170 countries, whatever their size or sector. By gaining full ISO 9001:2015 certification for our Quality Management System (QMS), Ceramicx can focus on increasing our performance and productivity while taking the next step as infrared industry leaders.

Over the summer, we’ve all had to navigate our way through COVID lockdowns, shutdowns, and restrictions, but as the autumn rolls around, things are changing. More of us are getting back to work and we’re all getting out and about again. But with a change in the season comes the need for heat – inside and out. And Ceramicx infrared technology continues to keep customers and workers warm.

Over the summer, we’ve all had to navigate our way through COVID lockdowns, shutdowns, and restrictions, but as the autumn rolls around, things are changing. More of us are getting back to work and we’re all getting out and about again. But with a change in the season comes the need for heat – inside and out. And Ceramicx infrared technology continues to keep customers and workers warm.

Ceramicx Annual shut down will take place from July 31st to August 18th, 2020.

Ceramicx Annual shut down will take place from July 31st to August 18th, 2020.