Square Flat Element Hollow

Showing all 11 results

-

Composite Pre-Heat Oven

Learn moreA UK based company specialising in the coating and laminating of complex textiles, and cutting of carbon composite materials, had issues with processing their materials which due to their nature needed very accurate control.

-

Heat-Shrinking Test Unit For Automotive Sector

Learn moreTo improve an inefficient and slow manual system, Ceramicx were given the green light to design and build a standalone, multi-zone, infrared heating test unit. Using a series of SFEH 600W ceramic infrared heating elements, the system is custom-designed to give a faster process, with more efficiency and consistency in the heat-shrinking of plastic and textile cloth wrapping for rigid rubber tubing.

-

In-Line Thermoforming Oven Solution

Learn moreThe UK based company called Linpac Packaging provides rigid and flexible packaging solutions to customers around the world. They approached Ceramicx to design and build a new heating system that could integrate into their current machine.

-

Inline Material Processing Oven

Learn moreThe infrared oven was designed with 4 zones evenly spread throughout which allowed the heat to be evenly spread throughout the material giving an end result of a high quality material finish. Each zone was capable of being controlled to within 2°C of the specified setpoint which allowed for a fast heat up time and extremely accurate setpoint control.

-

Long Wave Composite Curing Oven

Learn moreCeramicx developed a composite curing oven, which was embedded in a robotic press cell for a variety of composite systems.

-

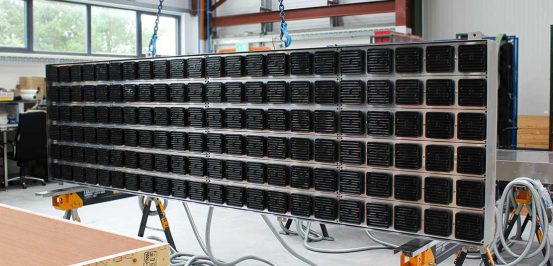

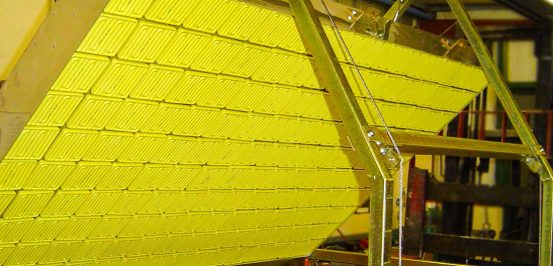

Modular Long-Wave Infrared Heaters In Composite Curing

Learn moreCeramicx SFEH black ceramic heating elements provided the higher temperatures required to fuse the materials, leading to faster curing times. Our inhouse Ceramicx team were then able to draw up drawings for a unique heating system, based on our own Modular IR 260 infrared technology.

-

MSE look to infrared to overcome system inefficiencies

Learn moreA key part of our recommendation was that their state-of-the-art machinery should be fitted with arrays of industry standard ceramic, square hollow elements (SFEH). With a flat body, these particular elements have a much shorter heat up time, increased energy efficiency, and have the ability to produce a diffused, radiant output-to-target distance.

-

Portable Test Oven

Learn moreCeramicx’ new Portable Test Stand allows for quick and consistent testing of materials. Various long, medium, and short wave Infrared emitters are fitted in a modified PAS, which is easily attached to the test stand.

-

Pre-Heat and Main-Heat System

Learn moreThese were used to produce an artificial turf type material for sports grounds in the US. There were 2 heating systems: pre-heat and main heat system to be positioned over a conveyor system.

-

Thermoforming System Upgrade for Insulation Provider

Learn moreSupplying the construction industry with a comprehensive range of insulation materials, the need for quality and efficiency led Xtratherm to choose Ceramicx for a more reliable and effective custom-built system.

-

Upgrading Food Packaging Thermoforming Lines

Learn moreThe client required a complete upgrade on one of its main plastics thermoforming lines – manufacturing consumables for the food service industries. The project scope included removal of the existing oven and replacement of it with an efficient ceramic-based top and bottom panel heater infrared oven.